4140 round bar stock

4140 round bar stock with most complate dimention.

Diameter:16-500mm in Normalized or QT condition.

Black surface and Bright Surface are both workable.

4140 round bar stock with most complate dimention.

Diameter:16-500mm in Normalized or QT condition.

Black surface and Bright Surface are both workable.

OTAI increased its inventory of German standard 42CrMo4 plate since 2018, and now the daily inventory is 600 tons around.

Now OTAI 42CrMo4 plate daily inventory is 600 tons around.Otai own the most complete size in south China.the German standard 42CrMo4 plate inventory is abundant. conventional thickness of 12-180mm, each thickness range are most in stock, the quality of 42CrMo4 plate plate had been qualified by Bohle and other European steel enterprise.

No matter price and quality, that are the most concern point of the buyer, because the steel market chaos, in China.many people so-called they have 42 crmo4 plate stock,in fact is not so much as seen on the network, more just downloaded the picture from the Internet.

In the Spring Festival of 2020, the outbreak of the new coronavirus was in urgent need of a large number of masks, and many enterprises were in urgent need of mask machines to put into production.

But there were not much 42CrMo4 plate stocks in the Chinese steel industry at that time, but Otai was one of the few stockist which keep 42CrMo4 plate. In less than 7 days, Our 2CrMo4 plate which a thickness of 40-60 mm was sold out.

Our company guarantees:the inventory is sufficient to supply the huge demand of factories in South China. especially the factory of 2020 mask machines.In addition to mask machine companies.

In the local area ,more and more companies have learned from this time,OTAI is the 42CrMo4 plate with the largest size in South China, and it is quickly shipped, and provides one-stop cutting, milling and other processing services.,and be affirmed by more and more customers.

Mr. Chen from ShaoGuan City was very cautious when buying steel, and asked for the material MTC, so he was worried about getting fakes.

I told Mr. Chen: MTC, our family sure can provide it. but I believe once you search it online, every one can offer it.but to determine whether this company has real stock, genuine goods, it is best to come to our factory to check.

I can give you a spectrometer to see the ingredients. If you think that’s so far,and quite hard for you to come, we will use WeChat video calling. We have stocks of 42CrMo4 plates in hundreds tons, and we supply raw materials to the local mask machine.

The quality is definitely high quality,as it’s for mask machine, and we will not ruin our reputation because of an order. Later, Mr. Chen really drove hundreds kilometers to our factory to see the goods.

I saw that our warehouse really had such much goods in stock, and also saw our testing equipment: direct reading spectrometer, hardness tester, ultrasonic Testers, etc., also saw that many people came and did purchased, he signed a contract immediately, saying that they finally found a reliable supplier, whether it is 42CrMo4 or alloy steel or mold steel will purchase with us.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com

A new customer asked about 42CrMo4 Plate Annealed today,It’s thankful that market seems going tobe recover.

I want 42CrMo4 Plate Annealed in German quality

But the second email about 42CrMo4 Plate Annealed,it kind of made me upset.As there is not thing question about the steel technology or knowleage.Only said I am worry about the defect of Chinese steel,I want the German quality.

Of course,I have to admit that German steel quality is quite well,and all over people are know it,I guess.

Why he bought a terrible one

I talked more with him,and foud the reason,that he such worry about the quality problem,he bought a terrible batch from China,but the real reason is that he thought that all steel from China should be very cheap.

So he did tried his best to achieved the unreasonable prices,the price of 42CrMo4 Plate Annealed,even lower 20% than us.So I guess what he got just a carbon steel before.

Technical data of 42CrMo4 Plate Annealed

Finally,I told him, no matter you will purchased from China again,Remember 2 thing.

No.1 never think there are something crazy cheap price,espcial much lower than market price.it will make you pay for lesson.

No.2 Check the chemical data about the goods,if you can,to check the company own direct-reading spectrograph,than if would be much safe.

| ASTM A29/A29M | C | Si | Mn | P | S | Cr | Mo |

| 4140/G41400 | 0.35~0.40 | 0.20~0.35 | 0.70~0.90 | 0.025 Max | 0.025 Max | 0.80~1.10 | 0.18~0.25 |

| DIN 17220, EN 10083 | C | Si | Mn | P | S | Cr | Mo |

| 1.7225/42CrMo4 | 0.38~0.45 | ≤0.40 | 0.60~0.90 | 0.035 Max | 0.035 Max | 0.90~1.20 | 0.15~0.30 |

| GB/T 1229 | C | Si | Mn | P | S | Cr | Mo |

| 42CrMo | 0.38~0.45 | 0.17~0.37 | 0.50~0.80 | 0.030 Max | 0.030 Max | 0.90~1.20 | 0.15~0.25 |

| JIS G4105 | C | Si | Mn | P | S | Cr | Mo |

| SCM440 | 0.38~0.43 | 0.15~0.35 | 0.60~0.85 | 0.030 Max | 0.030 Max | 0.90~1.20 | 0.15~0.30 |

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com

Many friends asked for the steel code lately,then I collect some as below.

P1 – P19: LowCarbon Steel

P20-p39: Low Carbon, High Alloy Steel(plastic die Steel)

2 xx, xx, xx 4, 6 xx: Stainless Steel (Stainless Steel)

H1-h19: Chromium base (Chromium base – hot working steel)

Wx: Water Hardening Steel

Sx: Shock Resisting Steel

Ox: OilHardening Steel (Steel)

Ax: AirHardening Steel

Dx: High Carbon, High Chromium Steel

Mx: Molybdenum base (H.S.S.- high speed steel)

Low carbon, high alloy (p20-plastic die steel)

Lowcarbon, high alloy (p20-plastic die steel)

Lowcarbon, high alloy, free Machine (p20-free cutting)

StainlessSteel (420 – acid-fast steel)

1.2316: Highperformance stainless Steel (420 – high acid Steel)

1.2343: Chromiumbase (Chromiumbase -H11 – hot working steel)

1.2344: Chromiumbase (chromium-based -H13 – hot working steel)

Lowalloy steel (o1-oil steel)

1.2379: Highcarbon, high chromium steel (D2 — chromium steel)

SxxC: Plain Carbon steel(yellow card-s55c)

SUSxx: Stainless Steel, acid Steel – 420)

SCrx: Chromium Steel

SCMx: Chromium Molybdenum Steel (P20)

SKx: Carbon Tool Steel

SKSx: Low Alloy Steel (oil steel-o1)

SKD11: MediumHigh Alloy Steel(chromium-d2)

SKD6: Medium High Alloy Steel(Medium High Alloy Steel -H11)

SKD61: Medium High Alloy Steel(Medium High Alloy Steel –H13)

SKHxx: High Speed Steel (hs-m 2)

SUMx: Free Cutting Steel

SUJx: Bearing Steel

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com

According to the life of the mold into five grades, the requirements of mold steel:

Level NO1:more than a million times,

level NO2:is 500,000 to 1 million times,

level NO3:is 300,000 to 500,000 times,

level NO4: is 100,000 to 300,000 times, and level 5 is less than 100,000 times.

Hardness in HRC50 or so of steel, otherwise it is easy to wear, the injection of the product is prone to out of tolerance, so the selected steel should have good heat treatment performance, and in the state of high hardness has good cutting performance, of course, there are other considerations.

8407, S136, the United States of mold steel 420, H13, Europe’s 2316, 2344, 083, or Japan’s SKD61, DC53 (the original metal mold material, special circumstances use).

Strong corrosive plastic generally choose S136, 2316, 420 and other steel, weak corrosive in addition to mold steel S136, 1.2316, 420, and JIS SKD61, NAK80, PAK90.

It also have a great impact on the choice of mold materials, transparent parts and surface requirements mirror products, materials available are S136, 2316, NAK80, PAK90, 420, the transparency of the mold should be selected S136, followed by 420.

There are many pre-hard materials for the three-stage mold,mold steel grades are S136H, 2316H, 083H, and the hardness is HB270-340.

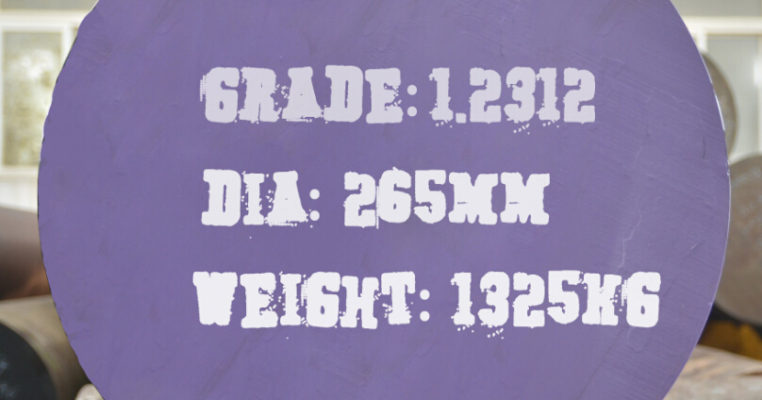

P20, OT718, 738, OT618, 2311, 2312, 2711 are used for grade 4 and grade 5 molds. For the molds with extremely low requirements, S50C and S45C steel may be used, which is to directly make a cavity on the mould blank.

If you want to know more or any suggestion,please conract me,let’s discuss more.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com

Classification of mould steels:Cold working steels、Hot mould steels、Plastic mould steels.

Such as AISI O1 Tool Steel、AISI D2 Tool Steel、JIS DC53 Tool Steel、JIS SKD11 Tool Steel

Cold working mould steel is mainly used to manufacture the die for pressing the workpiece in the cold state.

Such as cold blanking die, cold stamping die, cold drawing die, embossing die, cold extrusion die, thread pressing die and powder pressing die.

Cold working die steels range from carbon tool steels, alloy tool steels, high speed tool steels to powder high speed tool steels and powder high alloy die steels.

Such as DIN 1.2344 Tool Steel、AISI H13 Tool Steel、JIS SKD61 Tool Steel

Hot working die steel is mainly used to manufacture the die which is used to press the workpiece under high temperature condition.

Such as hot forging die, hot extrusion die, die casting die, hot upsetting forging die, etc.

The commonly used hot die steels are: medium and high carbon content alloy die steels with Cr, W, Mo, V and other alloying elements added;

Hot die steels with special requirements are sometimes made of high alloy austenitic heat resistant die steels.

Such as 1.2738 Tool Steel、AISI P20 Tool Steel、DIN 1.2311 &1.2312 tool Steel

As a result of the variety of plastic, the requirements of plastic products are also very different, the production of plastic mold materials also put forward a variety of different requirements.

Therefore, many industrial developed countries have formed a wide range of plastic mold steel series.

It includes carbon structural steel, carburized plastic mold steel, pre-hardened plastic mold steel, aging hardened plastic mold steel, corrosion-resistant plastic mold steel, easy-to-cut plastic mold steel, overall hardened plastic mold steel, martensitic aging steel and mirror polishing plastic mold steel.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com

There are three main ways to change the properties of die steel steel:Alloy composition、Smelting process、Heat treatment

Carbon: C

Increase the hardness of quenched tissue;

Forming carbide to improve wear resistance;

Reduced toughness;

Reduce weldability

Cr: Cr

Increase the hardness of steel, forming hard and stable chromium carbide, thus improving wear resistance;

Can improve the hardenability of steel;

When Cr content exceeds 12%, it is resistant to corrosion and provides good optical rotation

Mo, Mo

Mo is a strong carbide forming element to improve wear resistance.

Mo b b 0 0.5% can restrain the tempering brittleness caused by other alloy elements.

Provide red hardness, thermal intensity;

Increase the hardenability, temper stability

V: V

High hardness carbides can be formed to improve wear resistance.

Fine steel grain, reduce the sensitivity of overheating

Improve the strength, toughness and tempering stability of steel

Nickel: Ni

Ni can increase the hardenability of die steel;

Ni refines grains

Sulfur (S)

Often exists in steel in the form of MnS, breaks the continuity of matrix, deteriorates the material’s toughness, corrosion resistance, optical rotation, discharge processing, etch, can improve the cutting ability of the material.

Common steelmaking process

(1) electroslag remelting (ESR)

The thick billet is placed in the electroslag furnace, and a strong current is put into the furnace to produce a very high temperature, so that the thick billet is melted into molten steel, and the molten steel flows through the electroslag, and the impurities are filtered and absorbed by the electroslag, so as to achieve the purification effect.The overall remelting is fast, but some very fine impurities are not removed.

(2) vacuum arc remelting (VAR)

In a vacuum furnace, a strong electric current is applied to the steel shell. The bottom of the steel shell begins to melt, and the impurities are vaporized into gas and pumped away, thus improving the purity of the steel.It is characterized by thorough removal of impurities but slow overall remelting.

The heat treatment of die steel refers to the process of heating and then cooling, by controlling the heating temperature, holding time and cooling speed of steel to change the properties of steel, in order to meet the requirements of processing or use.The main heat treatment processes are: annealing, quenching, tempering.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com

In the production process of iron and steel plate products, when the blank is pressed, the surface wrinkle, the surface is not flat phenomenon, is a common punching defect.

This not only leads to the waste of raw materials, sometimes also increases the subsequent scrap, such as automotive stamping parts wrinkle, will directly lead to the welding process after welding poor quality or even welding joint cracking.So how does the wrinkling happen?

When the steel plate is pressed and deformed, it is subjected to the tensile stress in the plane drawing direction and the compressive stress in the plate thickness direction.Under certain pressure, the thinner the plate, the easier to wrinkle.

At the same time, during the processing, the maximum tangential compressive stress appears on the edge of the flange, that is, the wrinkle on the outer edge is the most obvious.

Is the product model reasonably taking into account the molding problem, is the press bar set too small?Does the place that crinkle easily need to add to absorb crinkle rib?

Solution: increase the bar or change the layout of the bar.Add wrinkle absorbent to scrap section.

A) the pressure surface is loose and tight

Solution: repair the grinding press surface.

B) unreasonable shape of filling surface

Solution: modify the shape of the feed surface to avoid the uneven material flow caused by its shape immobility.

C) reasons for blanks.The blank is too small or the blank is not positioned properly in the mold

Solution: increase the blank size.Improve the blank positioning on the mold so that the mold can accurately press the steel plate.

D) too little pressure

Solution: increase the mandrel pressure.

E) the gap between upper and lower modules is too large

Solution: adjust the gap.

F) the fillet radius of the die mouth is too large, which makes the punch unable to press the material

Solution: reduce the radius of the fillet.

G) too much grease

Solution: apply oil according to the requirements of the operation regulations to ensure the correct position and amount of oil applied

The yield strength of the material is not up to the standard and the material is too soft.

Solution: to ensure the product performance, the use of better formability of materials.

For different cases, specific problems need to be analyzed, but in the final analysis, it is still inseparable from the above principles.With such a train of thought, if encounter corresponding problem again, you do not need to worry about this little wrinkle again!

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com

The so-called non-quenched steel is a new kind of steel made by adding trace alloy elements such as V, Nb and Ti into medium carbon steel.In most cases the total amount of microalloys added is generally not more than 0.25% (0.25%).

The world’s first non-quenched steel was introduced in 1970 by GERLACH, a German company, which produced crankshafts using CK45 steel instead of the quenched steel they had just developed.Because the use of non-tempered steel production forgings can save the tempering treatment (quenching + high temperature tempering) in the process of two heating and energy consumption, so it has the advantages of energy saving and environmental protection, known as green steel.

In 1973, the Middle East war broke out, the high oil price forced people.they pay more attention to energy conservation and consumption reduction. Under this background, the development and utilization of non-quenched steel.it’s set off a climax in the west.with each country successively introducing its own non-quenched steel.By 1984, from non-quenched steel,60% of Japan’s crankshafts, 50% of its connecting rods were forged.The germans say, using 49MnVS3 non-quenched steel.It can instead of quenched steel.Aichi.A Japanese company, says that using non-quenched steel can cut costs by 18%.

Forgings, whether made of tempered steel or non-tempered steel.It cannot be used without strengthening treatment after forging.Different steels have different strengthening mechanisms.The strengthening mechanism of quenched steel is: First through quenching.The steel is made into martensite, and then the martensite is made into tempered sostenite by tempering treatment.

Rather than the reinforcement mechanism of quenched and tempered steel. first, in the heating process,non quenched and tempered steel V, Nb, Ti.Alloy elements in the form of alloy carbon compounds, before forging fully dissolve in the austenite. and then,in the process of cooling after forging.The carbon and nitrogen compounds from austenitic alloy precipitation.Forming numerous small, scattered alloy carbon compounds.At the same time, the fine ferrite steel can improve the strength and hardness of steel.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com

The development of non-quenched steel has gone through three stages.

The development of non-quenched steel has gone through three stages. The first generation of non-quenched steel is ferrite.Pearlite type non-quenched steel.The second generation is bainian type non-quenched steel.the third generation is low carbon martensionic type non-quenched steel.

At present, the largest amount of non – tempered steel, about 60% of the total amount.Compared with tempered steel, it has more strength than toughnes.So it is necessary to improve the toughness under the condition of guaranteeing the strength.

The Nippon steel researchers found,by properly controlling the production process.the austenite crystals were allowed to form a large number of ferrite nucleating cores.Then ferrite is formed not only in grain boundary, but also in austenitic crystal package.

These fine, evenly distributed ferrites make the steel remarkably more ductile.

It is a kind of strength and toughness is very good non quenched and tempered steel.In order to make the air cooling after forging can get bainite organization, after joined the molybdenum, manganese, boron in steel and other alloy elements.

When the content of it to a certain extent can make austenitic isothermal transformation curve is in the shape of epsilon to separate the steel C curve up and down;Boron can significantly delay ferrite transformation.

To boron or manganese – boron results in the bainite structure of steel over a wide cooling range.At the same time, manganese can reduce the phase change temperature.improve the toughness and enhance the strength.

Elements such as vanadium and chromium,they are usually added to low carbon bainitic steel,For makeing up for the decrease in strength caused,by the decrease in carbon content.

In 1988, an American steel company,first proposed the concept.third-generation non-tempered steel with low carbon tempered martensitic structure.

Similar to bainitic non-quenched steel, low carbon martensitic non-quenched steel has high toughness,as well as high strength.It has already been used in automobile walking parts and construction machinery.

At the same time, after the development and application of ferrite – pearlite (f-p), bainite (B), martensitic (M) non-quenched steel, ferrite – bainitic (F- B), ferrite – martensitic (F- M), composite phase non-quenched steel is gradually developed,and used because of low cost and excellent performance.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com

No comments by Sharon

Tel: 0086-769-23190193

Fax: 0086-769-88705839

WhatsApp: +8676923190193

Email (English): jack@otaisteel.com

Email (Español): jack@otaisteel.com

Address:

1F, Building B, Sanfang Industrial Area, Xiansha, Gaobu Town, Dongguan City, Guangdong Province, P.R. China

Subsidiary Company:

Dongguan Otai Metal Material Co., Ltd

Address: Room 615, Zhongsheng Commercial Building, #108 Hongfu Road, Nancheng Street, Dongguan City, Guangdong Province, China