4140 PH Steel: Leading the Way in Modern Manufacturing

4140 PH Steel: Leading the Way in Modern Manufacturing

In the world of advanced materials, 4140 alloy steel stands out as a symbol of strength and durability. With its distinctive mix of chromium and molybdenum, this high-performance alloy serves as the backbone of numerous precision-engineered components essential to industry.

The Alloy’s Composition: A Harmony of Power

Within 4140 alloy steel, a finely tuned interaction of elements creates a robust performance. Chromium enhances hardenability, while molybdenum boosts the steel’s resistance to wear. This combination of elements turns 4140 alloy steel into a leader in material strength.

Heat Treatment: Crafting Excellence

Similar to how a sculptor shapes their medium, heat treatment refines steel 4140 ph. Through careful quenching and tempering, the alloy’s inherent potential is unlocked, resulting in a surface hardness that offers robust protection against wear and damage.

Applications: 4140 Alloy Steel in Action

4140 alloy steel quietly excels in various applications, from engine gears to infrastructure fasteners. Its resilience under stress makes it a preferred choice for demanding environments.

Precision Machining: Perfecting Steel

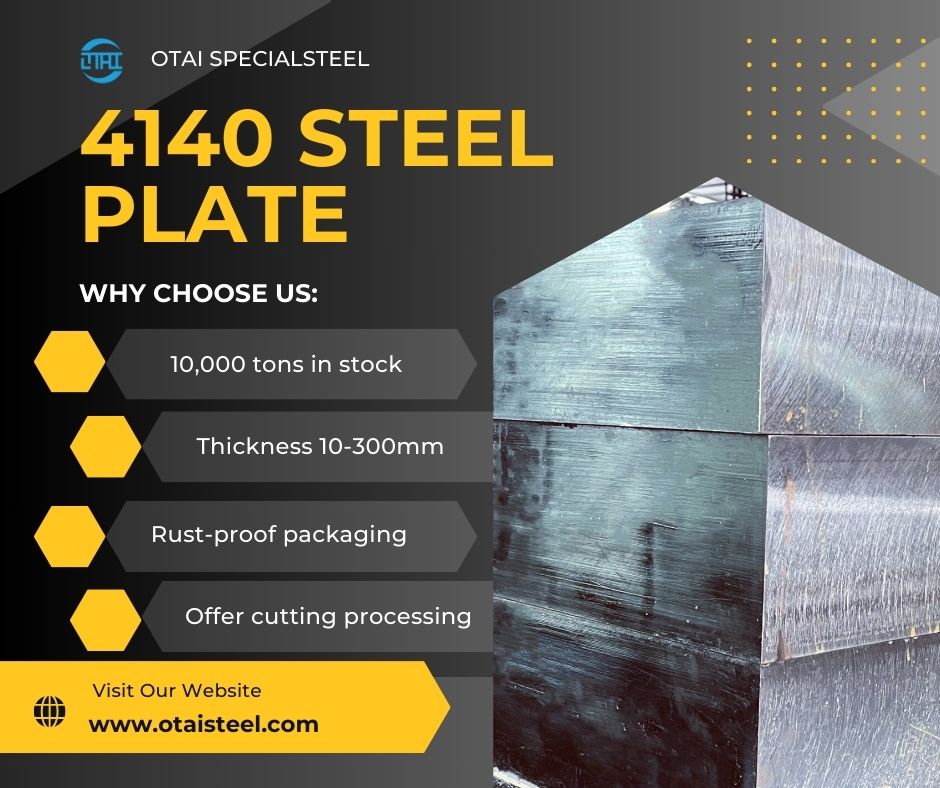

At OTAI, precision is paramount. Our advanced machining services ensure that every 4140 alloy steel component is crafted to exact standards, converting raw material into finely tuned parts.

4140 vs. 4340: A Comparison of Alloys

4140 and 4340 alloy steels often compete in the alloy arena, each with unique strengths. The choice between them hinges on the specific requirements of the application.

Hardness and Fatigue: A Twin Force of Durability

The hardness of 4140 alloy steel defends against abrasive forces, while its fatigue resistance guards against ongoing stress. Together, they create a strong foundation for components enduring tough conditions.

The Welding Challenge: Joining with Precision

Welding steel 4140 ph demands a careful approach due to its complex composition. Proper attention to welding parameters is crucial to ensure joints are strong and maintain the steel’s qualities.

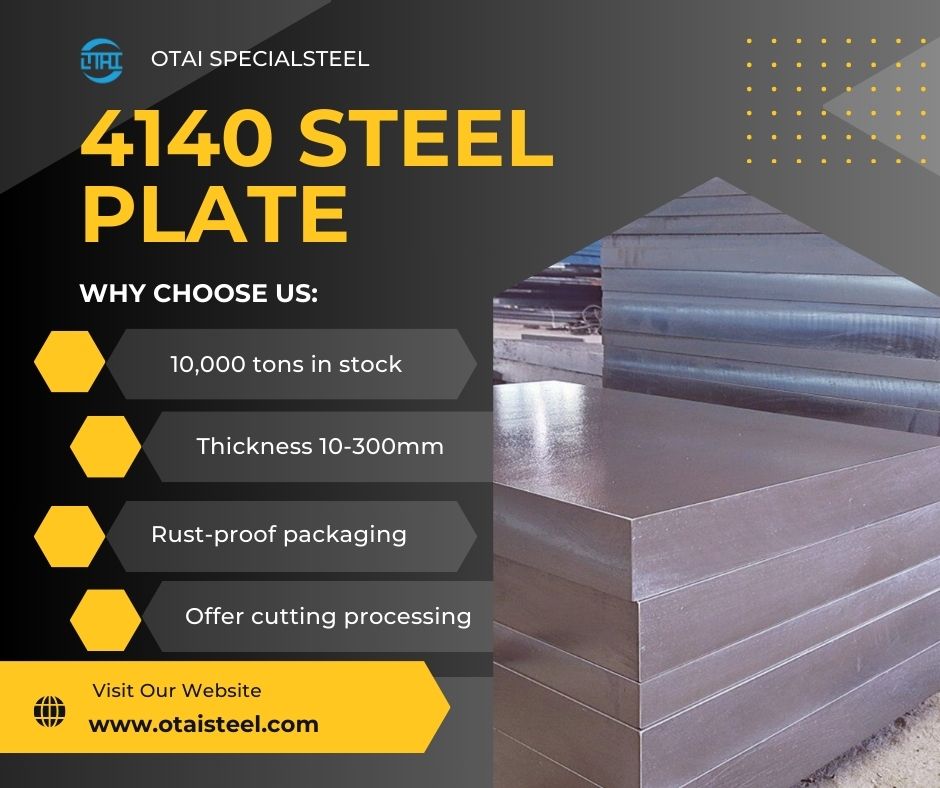

Stock and Supply: Ensuring Availability

At OTAI, we maintain 10,000 tons of stock and an efficient supply chain for 4140 alloy steel, guaranteeing consistent availability for our clients.

Conclusion: 4140 PH Steel: Leading the Way in Modern Manufacturing

4140 alloy steel represents a commitment to engineering excellence. OTAI’s focus on delivering top-quality 4140 alloy steel, coupled with precision machining and cutting services, establishes us as a reliable partner for those seeking the best in materials.

OTAI’s Versatility in 4140 Steel Plates: An Overview of Available Thickness Options

OTAI’s Versatility in 4140 Steel Plates: An Overview of Available Thickness Options How to Properly Quench 4140 Steel for Maximum Strength

How to Properly Quench 4140 Steel for Maximum Strength Understanding What Makes Forged 4140 Steel Exceptional

Understanding What Makes Forged 4140 Steel Exceptional Advancing AISI 4140 Steel’s Functionality via Alloying Element Adjustments

Advancing AISI 4140 Steel’s Functionality via Alloying Element Adjustments A Deep Dive into the Exceptional Qualities of 4140 Steel

A Deep Dive into the Exceptional Qualities of 4140 Steel Chrome-Plated Hardened Multipurpose 4140 Alloy Steel Rods

Chrome-Plated Hardened Multipurpose 4140 Alloy Steel Rods Navigating the 4140 Steel Processing Journey: From Material to Cut

Navigating the 4140 Steel Processing Journey: From Material to Cut Fundamental Uses of 4140 Ground Flat Bar in Production Systems

Fundamental Uses of 4140 Ground Flat Bar in Production Systems 4140 Steel Plate Price: Navigating the Complexities of Alloy Steel Cost

4140 Steel Plate Price: Navigating the Complexities of Alloy Steel Cost