34CrNiMo6 Intorcution –Properties/chemical/application/heat treatment

34CrNiMo6 steel Intorcution –Properties/chemical/application/heat treatment

34CrNiMo6 is equal to 1.6582 .

The chemical of the grade for 34CrNiMo6 and 1.6582 as the below sheet :

| Grade | C | Mi | Si | P | S | Cr | Ni | Mo | |

| 34CrNiMo6 | 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.025 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | |

| C | Mi | Si | P | S | Cr | Ni | Mo | ||

| 1.6582 | 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.035 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 |

The application of 34CrNiMo6:

34CrNiMo6 is a typical difficult-to-machine material, widely used in the manufacture of important parts such as camshafts and connecting rods of engines.

The 34CrNiMo6 alloy is high-strength. Because of its excellent comprehensive mechanical properties, it is widely used in the manufacture of engine camshafts and connecting rods and other important parts.

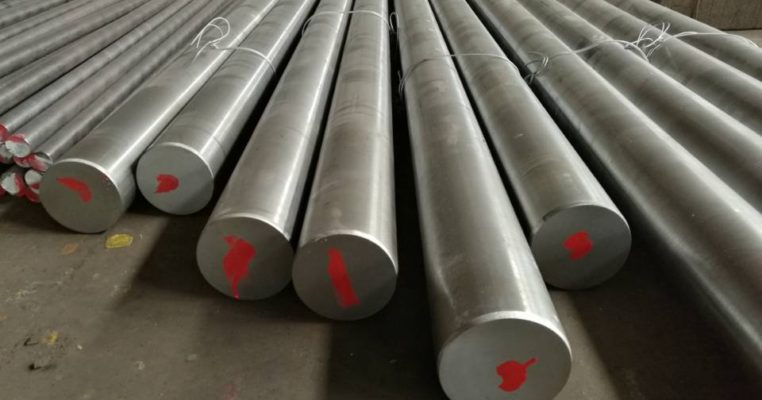

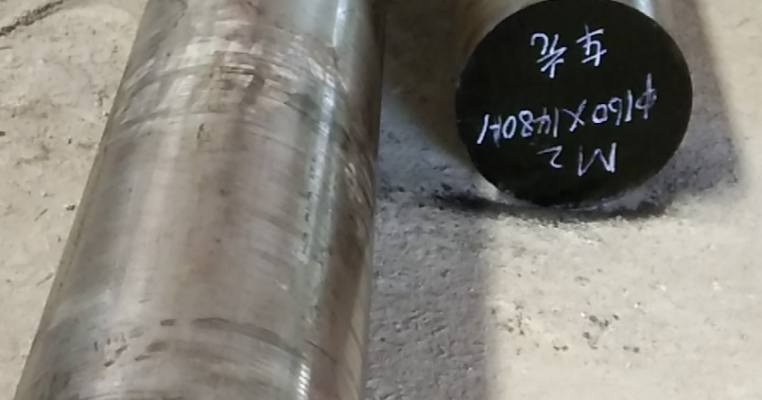

The stock for the specification as the below :

| Grade | Item | Size |

| 34CrNiMo6 | Cold drawn round bar | Dia.3-100 |

| 34CrNiMo6 | Hot rolled steel plate | Dia.5-100 |

| 34CrNiMo6 | Hot rolled round bar | Dia.100-200 |

| 34CrNiMo6 | Hot rolled round bar | Dia.20-100 |

| 34CrNiMo6 | Hot rolled round bar | Dia.200-400 |

Mechanical properties of 34CrNiMo6 as the below mention :

After 34CrNiMo6 material is quenched and tempered, the hardness is 36-40 HRC, the tensile strength σb is 1 100 MPa, the elongation δ is 12%, and the impact toughness value ακ is 8 kg / cm2.

Heat treatment:

The tempering process of 34CrNiMo6 is 850 oil quenching and 580 degree tempering.

Quenched and Tempered (Q+T) of 34CrNiMo6 Steel

- Heat 34CrNiMo6 round steel slowly to the temperature of 850°C;

- Soak at this hardening temperature quench in oil;

- Temper as soon as 34CrNiMo6 steels reach room temperature.

- Heat uniformly to the suitable temperature;

- Withdraw from the furnace and cool in the air.

- The usual tempering temperature is 600°C which depending on the actual requirements.