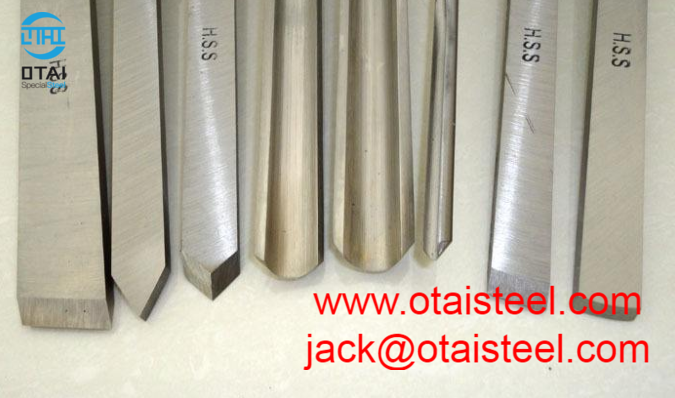

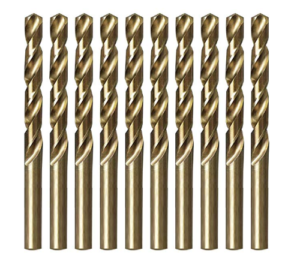

The quality of tooling material(HSS material or Alloy steel ) is the basic factor, which affects the machining surface quality, cutting efficiency and lifecycle of tools. The cutting part of the tools responsible for cutting work directly of tools .it is so important to choose the tool material in reasonable .

-

High hardness and wear resistance

Hardness is a basic characteristic of tool material (HSS material) .The hardness of the cutting tool must be greater than the cutting material .The hardness of cutting edge used in cutting metal is generally above 60HRC.Wear resistance is the ability of a HSS material to resist wear and tear.

-

High heat resistance (thermal stability)

Heat resistance is the main indicator of tool materia’sl (HSS material or alloy steel ) cutting performance. It refers to the tool material under high temperature conditions still maintain a certain hardness, wear resistance, strength and toughness . The cutting tool material should also have the ability to resist oxidation at high temperature ,resist bonding and diffusion. So the cutting tool material should have good chemical stability.

-

Good thermophysical property and thermal shock property

The better the thermal conductivity of the tool material, the more easily the cutting heat dissipates from the cutting area which helps to reduce the cutting temperature. In intermittent cutting or using cutting fluid. The tool is often subjected to a large thermal shock (temperature changes dramatically), resulting in cracks in the tool leading to fracture.

-

Good process performance

In order to facilitate the manufacture of the tool, the tool material (HSS material and Alloy steel ) is required to have good process performance. Such as forging performance, heat treatment performance, high temperature plastic deformation performance, grinding performance.

-

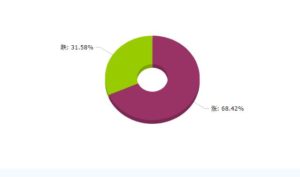

Economy

Economy is one of the important indicators of cutting tool material. Although the cost of high-quality cutting tool material is very high, its long life-cycle, the cost allocated to each part is not necessarily very high. Therefore in the selection of cutting tool materials to consider its economic influence .

Ms Elwa Lee

Mobile/WhatsApp: 0086-15899675236

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Elwa@otaisteel.com