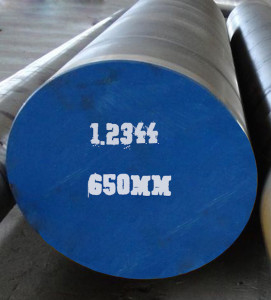

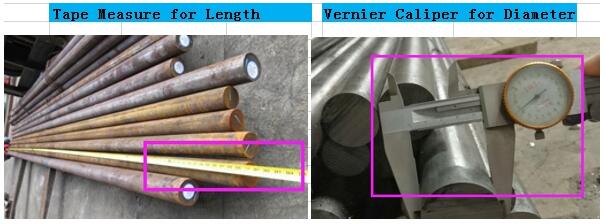

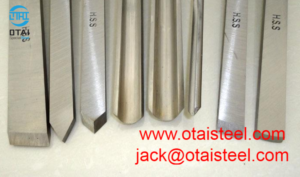

OTAI STEEL specializes in 34CrNiMo6 alloy steel, which can provide customers with regular sizes from Φ10mm to Φ500mm. Sufficient inventory and 21 years of professional experience let us to not only professionally control the quality of raw materials and heat treatment processes.

As Chinese Lunar Year coming soon ,we got the feedback from our customer who order 4140 Round Bar Hot Rolled Alloy Steel from us that they need to delay their import process ,and let us help to ” Freetime extention ” of containers shipment .