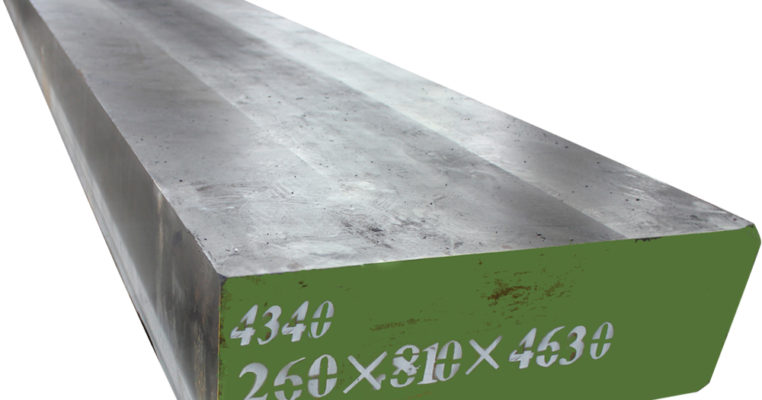

Chromium-nickel-molybdenum steel: represents steel type 4340/34CRNIMO6.It has excellent comprehensive mechanical properties.

4340/34CrNiMo6

Chromium-nickel-molybdenum steel: represents steel type4340/34CrNiMo6.It has excellent comprehensive mechanical properties, high impact toughness at low temperature, low notch sensitivity and no tempering brittleness.Used for making large crankshaft, shaft, connecting rod, gear, bolt and other parts with large force and complex shape.

More application of tempering steel

(1)

Cr,ni, mo, v steel: 45CrNiMoVA for steel type.High strength, good tempering stability, oil quenching up to 60mm (95% martensite).It is used to manufacture elastic shaft and torsion shaft of heavy truck under vibration load.

(2)

Chromium silicon steel: on behalf of the steel type 38CrSi.Hardenability is better than 40Cr, the strength and low temperature impact are higher, the tempering stability is better, the tempering brittleness tendency is greater.It is commonly used to manufacture 30-40mm shafts, bolts and gears with small modulus.

(3)

Chromium molybdenum steel: on behalf of steel 30CrMoA, 4140, ML30CrMo, ML42CrMo.Water quenching 30-55mm, oil quenching 15-40mm;High mechanical properties at room temperature, high strength at high temperature and good impact at low temperature;No tempering brittleness.Used for making parts with large section, bolts and gears with high load and flanges and bolts under 500℃;Conduit and fastener under 400℃.4140 has higher hardenability than 30CrMoA and is used for making parts with higher strength and larger cross sections.

(4)

Chromium manganese molybdenum steel: on behalf of the steel 40CrMnMo.The diameter of oil quenching is 80mm, with high comprehensive mechanical properties and good tempering stability.Used for manufacturing heavy load gear and shaft parts with large section.

(5)

Manganese molybdenum vanadium steel: on behalf of the steel 30Mn2MoWA.Good hardenability: water quenching up to 150mm, the heart structure is upper and lower bainite plus a small amount of martensite;Oil quenching 70mm, more than 95% martensite in the heart;Good low temperature impact toughness, low notch sensitivity and high fatigue strength.It is used to manufacture important parts under 80mm.

(6)

Chromium manganese silicon steel: on behalf of the steel 30CrMnSiA.Water quenching 40-60mm (95% martensite), oil quenching 25-40mm.High strength, impact toughness, temper brittleness.Used for manufacturing high pressure blower blade, valve plate, clutch friction plate, shaft and gear.

(7)

chrome-nickel steel: on behalf of the steel 40CrNi and 45CrNi.Water quenching up to 40mm, oil quenching up to 15-25mm;Good comprehensive mechanical properties, good low temperature impact toughness, little tempering brittleness.30CrNi3A has high hardenability, good comprehensive mechanical properties, white point sensitivity and temper brittleness.Used for making large section of crankshaft, connecting rod, gear, shaft and bolt.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com