42CrMo4 4140 material is an important steel type as a reducer structural part. For parts made of this steel, it is required to have comprehensive mechanical properties with good combination of strength and toughness. Because the equipment, materials and process technology operations are difficult to master at present. Some parts are prone to cracking during the tempering process. And these parts have obvious characteristics compared with other parts. Only by fully mastering these characteristics can we obtain satisfactory results. .

Generally speaking, the main factors affecting the quality of forging quenching and tempering include as following.

(1) Ingredient segregation. 42CrMo4 4140 steel is a medium carbon alloy structural steel, and its raw materials often have band-shaped segregation. From the analysis results of 42CrMo4 band component segregation energy spectrum, it can be seen that the Mo content in the ferrite band is 5-6 times higher than that in the pearlite band. The enrichment of some elements in the segregation stripes is very serious.

(2) Gas and inclusions. 42CrMo4 steel, especially the raw materials with large cross-section, inevitably contains gas and inclusions. For medium carbon alloy structural steel, due to the segregation of carbon and alloy elements, it may cause forgings Cracking occurs at the segregation. In addition, the presence of aluminum elements is also harmful to steel.

(3) Forging temperature. As this steel is segregated inside. When it is heated close to the solidus in an oxidizing atmosphere, if the high temperature duration is too long, it is easy to produce precipitates or impurities. Due to the low melting point, the grain boundary of the metal may start to melt. Oxygen invades through the melted grain boundary and forms oxides on the grain boundary. This will cause local over-firing and form one of the major defects in subsequent thermal processing.

(4) Forging ratio. When the forging ratio is insufficient, the deformation of the center of the workpiece is small. And the segregation and the original ingot structure of the steel ingot are still partially retained. If the forging ratio is too large, the anisotropy of mechanical properties increases, and the transverse mechanical properties decrease more.

Experimental research shows that due to problems of forging process and heat treatment process. 42CrMo4 4140 steel obtains mixed structure and complex stress distribution after quenching. And the workpiece is often cracked in batches or more. No matter what original state 42CrMo steel is sub-temperature quenched. The impact toughness after high temperature tempering is significantly better than conventional quenching and tempering. The controllable gas multi-purpose furnace is used for easy-cracking forgings for isothermal quenching, high temperature tempering and more stable.

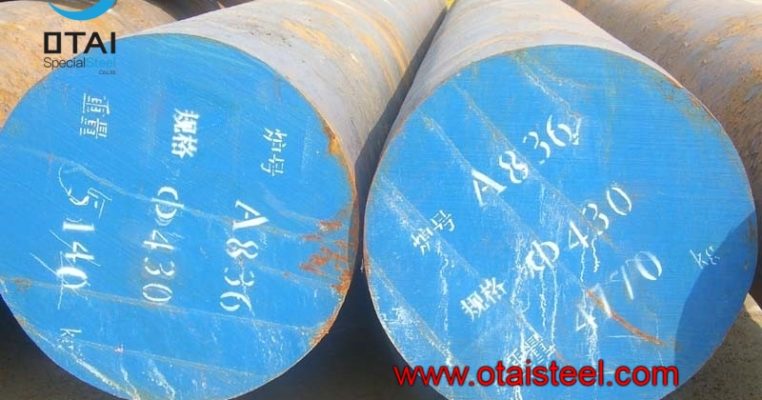

Our Otai does not act as material handler. We have our own technique as we are on this steel field for more than 21years. We cut down the cost for distributor, and solve the different kinds of difficulties for the end users.

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: jack@otaisteel.com