seamless steel 440 is a kind of economic section steel. it is widely used in the manufacture of structural parts. Otai company provides it for our clients.

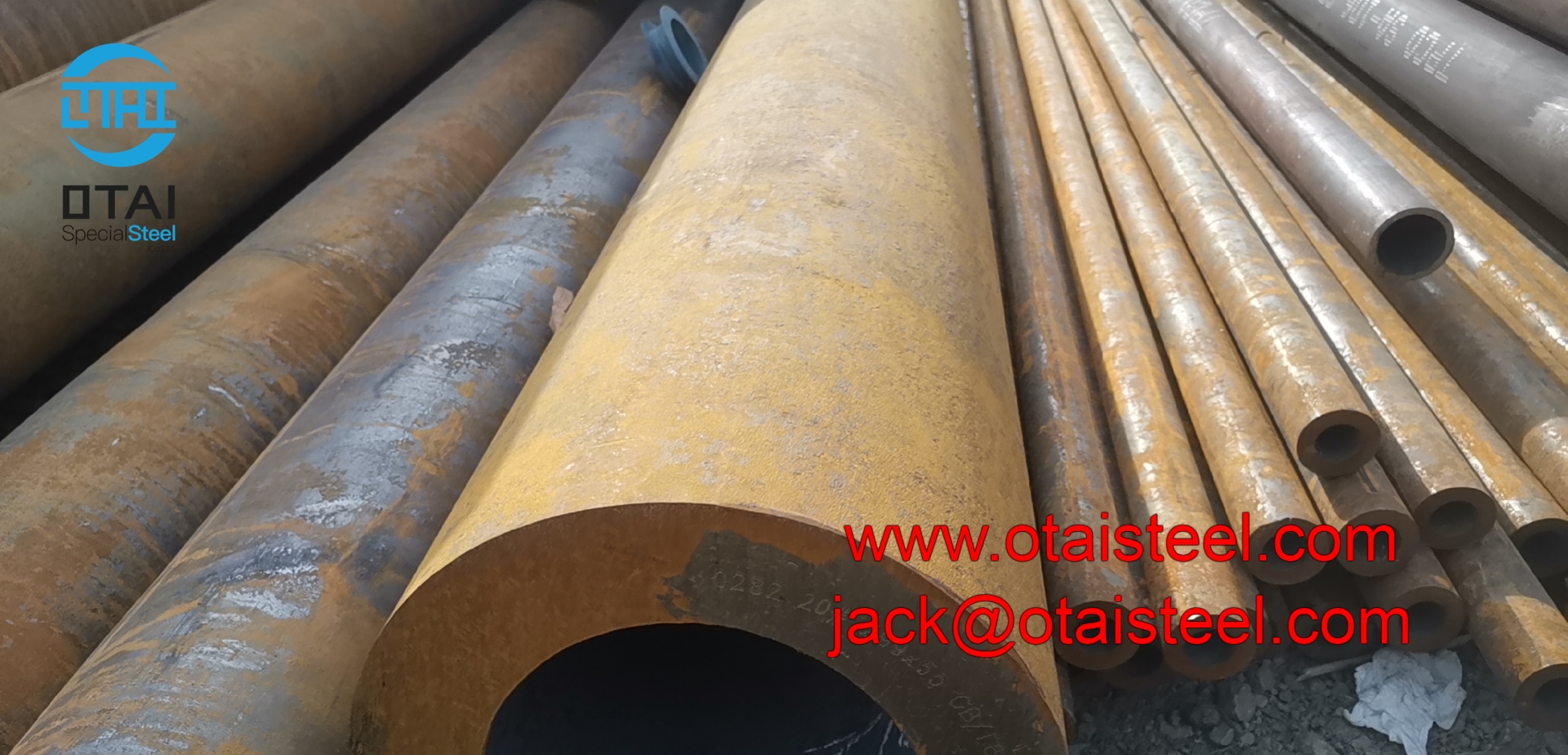

Seamless steel tube is a round, square, rectangular steel with a hollow section and no joints around it. A seamless steel tube is made of the ingot or solid tube blank through the perforation into a capillary tube, and then by hot rolling, cold rolling, or cold drawing. Otai company provides Seamless steel 440 for our clients.

Seamless steel pipe has a hollow section, a large number of pipe used for conveying fluid, steel pipe and round steel and other solid steel, in the same bending and torsional strength, weight is lighter, is an economic section of steel, widely used in the manufacture of structural parts and mechanical parts, such as oil drilling steel scaffolding.

Use and classification of seamless steel tube

Application: A seamless steel tube is a kind of economic section steel, which has a very important position in the national economy. It is widely used in petroleum, chemical industry, boiler, power station, ship, machinery manufacturing, automobile, aviation, aerospace, energy, geology, construction, and military industry.

Classification:

(1)According to the section shape: circular section tube, shaped section tube

(2)According to the material: carbon steel pipe, alloy steel pipe, stainless steel pipe, composite pipe

(3)According to the connection: threaded connection pipe, welding pipe

(4) according to the production mode: hot rolling (extrusion, top, expansion) tube, cold rolling (drawing) tube

(5) according to the use of the following: boiler pipe, oil well pipe, pipeline pipe, structure pipe, fertilizer pipe

Seamless steel tube production process

(1) main production process of hot rolled seamless steel pipe (main inspection process) :

Preparation and inspection of tube billet → tube billet heating → perforation → rolling pipe → reheating of raw pipe → fixing (reducing) diameter → heat treatment → straightening of finished pipe → finishing → inspection (nondestructive, physical and chemical, table inspection) → storage

(2) cold rolling (drawing) seamless steel pipe main production process

Blank preparation → pickling lubrication → cold rolling (drawing) → heat treatment → straightening → finishing → inspection

If you want to know more about stainless steel 440, welcome to contact me.