High Speed Steel –M2 with good quality and high hardness

There a column mentioned a question that does the high speed steel M2 can be made a kitchen knife ?

It is a common that all high speed steel with good quality because its own with high alloy chemical in sheet chart but it is doesn’t mean that can work every thing by M2 tool steel .

M2 tool steel generally application in the heavy industrial ‘s knife , such as the drill , Moulds suitable for shock and impact loads: deep-drawing dies, punching dies. Metal cutting saw blades, cold heading and extrusion tools.

From the perspective of ensuring specific hardness, Mo and W have similar effects. This steel has the advantages of small carbide unevenness and high toughness, but there are two major disadvantages, which limits its application.

First, the tendency of decarburization is large, so the heat treatment protection requirements are strict. Second, the tendency of grain growth is large, and it is easy to overheat, so the quenching heating temperature should be strictly controlled.

Mould steel characteristics M2 high-speed steel is a molybdenum-based high-speed tool steel. From the perspective of ensuring specific hardness, Mo and W have similar effects. This steel has the advantages of small carbide unevenness and high toughness, but there are two major disadvantages, which limits its application.

First, the tendency of decarburization is large, so the heat treatment protection requirements are strict; second, the tendency of grain growth is large, and it is easy to overheat, so the quenching heating temperature should be strictly controlled.

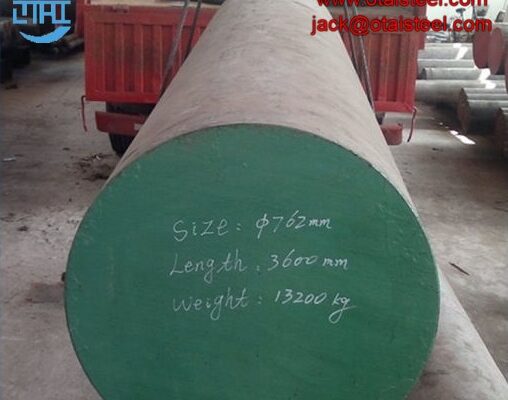

Delivery status and hardness Annealed, hardness 248HBS; cold-drawn, hardness 262HBS; cold-drawn, annealed hardness 255HBS.

Typical chemical composition (mass fraction,%) of M2 high speed steel C 0.78 ~ 0.88, Si 0.20 ~ 0.45, Mn 0.15 ~ 0.40, P≤0.030, S≤0.030, Cr 3.75 ~ 4.50, Mo 4.50 ~ 5.50, V 1.75 ~ 2.20, W 5.50 ~ 6.75.

Hot working specifications The starting temperature is 1040 ~ 1150 ℃, and the ending temperature is 930 ℃.

Annealing specification Temperature 820 ~ 870 ℃, hardness 207 ~ 235HBS after annealing.

General quenching and tempering specifications The quenching temperature is 1190 ~ 1230 ℃, the quenching medium is oil, air cooling or salt bath, the tempering temperature is 540 ~ 600 ℃, and the hardness is 65-60HRC.

Die quenching and tempering specifications Preheating temperature 730 ~ 850 ℃, quenching temperature salt bath furnace 1216 ℃, controlled atmosphere furnace 1227 ℃, tempering temperature 550 ℃, hardness after tempering≥64HRC

Typical application examples of M2 high speed steel

① Moulds suitable for bearing shock and impact loads: deep-drawing dies and punching dies.

② Metal cutting saw blades, cold heading and extrusion tools.