High Speed Steel –M2 with good quality and high hardness

Difference grade with difference chemical component chart .

All depend on your standard’s request .

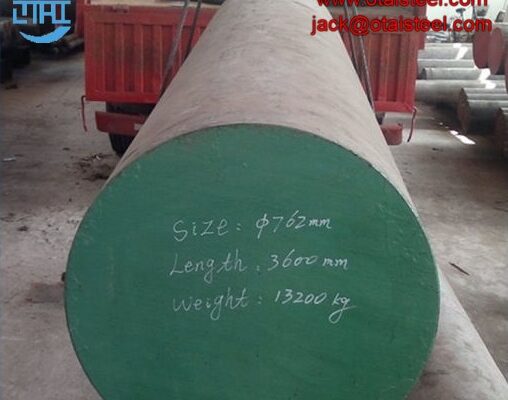

All grades of the above that we can supply with you for the regular size in our stock .

M2 high speed steel with great hardness so its appliance to many high-end part in the machine or life service .

hemical composition editing

Carbon C: 0.80 ~ 0.90 (Allowable deviation: ± 0.01)

Silicon Si: 0.20 ~ 0.45 (Allowable deviation: ± 0.05)

Manganese Mn: 0.15 ~ 0.40 (allowable deviation: +0.04)

Sulfur: ≤0.030

Phosphorus P: ≤0.030

Chromium Cr: 3.80 ~ 4.40 (Allowable deviation: ± 0.05)

Nickel Ni: Allowable residual content ≤ 0.30

Copper Cu: Allowable residual content ≤0.25

Vanadium V: 1.75 to 2.20 (permissible deviation: ± 0.05)

Molybdenum Mo: 4.50 ~ 5.50 (Allowable deviation: size≤6, ± 0.05; size> 6, ± 0.10)

Tungsten W : 5.50 ~ 6.75

Note: According to the agreement between the supply and demand sides, the content of V can be 1.60 ~ 2.20

The main purpose:

Cold forging die, fine blanking die, powder pressing die, etc. Shear die, plastic die with glass fiber, etc. Moulds suitable for shock and impact loads: deep-drawing dies, punching dies. Metal cutting saw blades, cold heading and extrusion tools.

Solidification edit

The effect of Ce on the solidification structure of M2 high-speed steel and its mechanism were studied. It was found that Ce in high-speed steel can reduce the segregation of alloying elements such as W and Mo, and reduce and refine the amount of eutectic carbides. Ce is mainly segregated at the interface between grain boundary eutectic carbides and austenite, with some Ce. Participates in the formation of Ce-containing M2C carbides; Ce promotes network breakage and pelletization of eutectic carbides when heated at high temperatures.