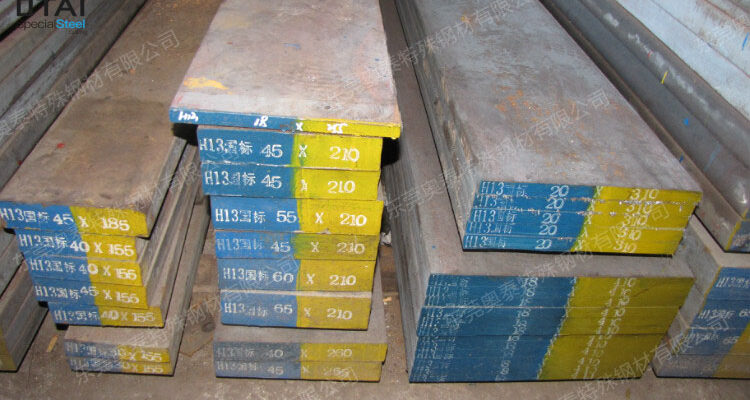

Our H13 STEEL -chapter 6

The behavior of alloy carbides in steel is related to their own stability. In fact, the structure and stability of alloy carbides of H13 are related to the electron deficiency of the d-electron shell and the S-electron shell of the corresponding C-forming elements [17]. As the electron deficiency decreases, the metal atomic radius decreases, the atomic radius ratio of carbon and metal elements increases, and the alloy C compounds change from interstitial phase to interstitial compound. The stability of H13 the C compound decreases, and its corresponding melting temperature and The lower the dissolution temperature in A, the absolute value of its free energy of generation decreases, and the corresponding hardness value decreases. VC carbides with face-centered cubic lattices have high stability. They begin to dissolve at about 900 ~ 950 ° C, and begin to dissolve in large quantities above 1100 ° C (dissolution end temperature is 1413 ° C) [17]; it is at 500 ~ 700 ° C. H13 precipitates during the tempering process, is not easy to grow up, and can be used as a strengthening phase in steel. M2C and MC carbides formed by medium carbide forming elements W and Mo have close-packed and simple hexagonal lattices, they are less stable, and they also have higher hardness, melting point, and melting temperature. They can still be used at 500 ~ A strengthening phase of steel is used in the 650 ° C range. M23C6 (such as Cr23C6, etc.) has a complex cubic lattice, worse stability, weaker bonding strength, lower melting point and melting temperature (dissolved in A at 1090 ℃), only after comprehensive alloying in a few heat-resistant steels Only have higher stability (such as (CrFeMoW) 23C6, can be used as a strengthening phase. M7C3 (such as Cr7C3, Fe4Cr3C3 or Fe2Cr5C3) with complex hexagonal structure) has worse stability. It is as easy to dissolve and precipitate as Fe3C type carbide , Has a large aggregation and growth rate, and generally cannot be used as a high-temperature strengthening phase [17].