Basic information OF D3

D3 steel, High carbon Alloy tool steel is a high chromium Leysite steel. It has high wear resistance, hardenability, toughness, thermal stability, compressive strength, excellent micro-deformation and comprehensive performance, good machining and thermal oxidation resistance, and wide adaptability.

Application

a) It is mainly used as a silicon steel sheet die for stretching and punching molds that require high wear resistance and simple shape under small dynamic load conditions.

b It is used to manufacture punches, dies and inserts that require high wear resistance and complex shape in bending dies. It is recommended to make punches and dies, and the hardness is 60~64HCR.

c) It is used to manufacture the die which requires wear resistance in the drawing die. The recommended hardness is 62~64HCR.

d) When used for the punch of aluminum cold extrusion die, the recommended hardness is 60~62HCR.

e) For bending steel with a carbon content of 0.65%~0.80%, the hardness is 60~62HCR.

f) It can be used for blanking die, punch, rolling wheel, scissor blade, cold pier mold and clay mold.

g) It can be used for thermosetting plastic molding dies and the like.

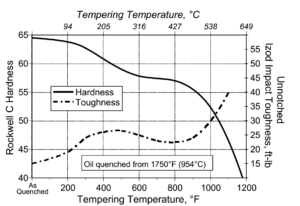

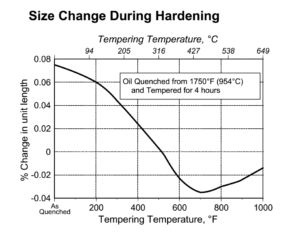

Reference pictures:

D3 High Carbon Alloy tool steel

|

AISI / SAE |

DIN / W.Nr |

JIS |

GB |

|

D3 |

1.2080 |

SKD1 |

Cr12 |

|

Steel |

C |

Si |

Mn |

P |

S |

Cr |

|

1.2080 |

1.90 |

0.10 |

0.20 |

≤ |

≤ |

11.00 |

|

D3 |

2.00 |

0.10 |

0.20 |

≤ |

≤ |

11.00 |

|

Cr12 |

2.00 |

≤ |

≤ |

≤ |

≤ |

11.50 |

|

Shape |

Thick / Dia. (mm) |

Width (mm) |

|

Round |

8-500 |

/ |

|

Flat |

6-200 |

20-900 |

|

Block |

150-500 |

200-800 |

Delivery Condition

Characteristics

Contact

Email: Jack@otaisteel.com

Tel: +86-769- 23190193

Fax: +86-769-88705839