4130 Alloy Steel | 1.7218 | 25CrMo4 | P280GH | 2244 | SMn420

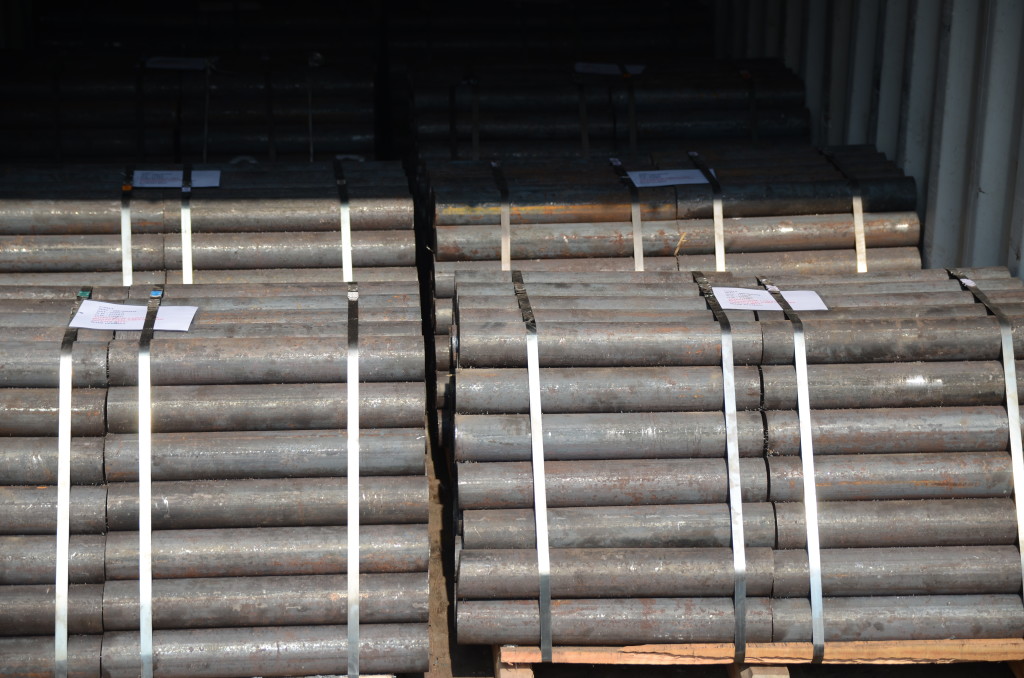

Oil and Gas industry Steel

AISI 4130 Steel is a Alloy Structural Steel belong to ASTM A29/A29M Steel Grade standard. AISI 4130 used in Oil and Gas industry and Large Machinery Structural. 4130 China Supplier and factory Otai Special Steel Supply 4130 steel in Round bar, Plate, Flat bar, Square, Forging Ring and others any shape. And provide cutting, sawing, milled, machining processing. Download Full Datasheet

Supply Form of 4130 Steel -ASTM A29/A29M Alloy Structural Steel

- Round

- Plate

- sheet

- Square

- Pipe

- Hexagonal

Supply Range of AISI 4130 Alloy Steel

4130 Steel Round Bar: diameter 5mm – 400mm

4130 Steel Plate: thickness 5 –500mm x width 200– 2300mm

4130 Steel Block: 210mm x 500-810mm

Chemical Composition of AISI 4130 Alloy Steel Material

| ASTM A29/A29M | C | Si | Mn | P | S | Cr | Mo |

| 4130/G41300 | 0.28~0.33 | 0.15~0.35 | 0.40~0.60 | 0.035 Max | 0.045 Max | 0.80~1.10 | 0.15~0.25 |

| DIN 17200, EN 10083 | C | Si | Mn | P | S | Cr | Mo |

| 1.7218/25CrMo4 | 0.22~0.29 | ≤0.40 | 0.60~0.90 | 0.035 Max | 0.035 Max | 0.90~1.20 | 0.15~0.30 |

| GB/T 1229 | C | Si | Mn | P | S | Cr | Mo |

| 25CrMo | 0.20~0.30 | 0.17~0.37 | 0.40~0.70 | 0.030 Max | 0.030 Max | 0.80~1.10 | 0.15~0.25 |

| JIS G4105 | C | Si | Mn | P | S | Cr | Mo |

| SMN420/SCM420 | 0.18~0.23 | 0.15~0.35 | 0.60~0.85 | 0.030 Max | 0.030 Max | 0.90~1.20 | 0.15~0.30 |

4130 alloy Steel Equivalent and Related Speciation

| USA | German | Japan | China | ISO |

| ASTM 29/A29M | DIN 17350 | JIS G4404 | GB/T 1229 | ISO 683/18 |

| 4130 | 1.7218/25CrMo4 | SMN420 | 25CrMo | 25CrMo4 |

ASTM AISI 4130 alloy Steel Material Mechanical Properties

Hardness, Rockwell C: 22 HRc, Density: 7.85kg/m3

Tensile strength: 655 MPa .

Melting point: 1416°C

Thermal expansion: 12.2 µm/m°C (20-100 ºC)

Elastic modulus: 190-210 GPa (at 25 ºC ).

Forged of AISI 4130 Oil and Gas industry Steel material metal

Forged AISI 4130 at 1150-1200 ºC. no forging when below 850 ºC.

Heat Treatment of SAE/AISI 4130 Alloy Steel

- 4130 Steel Annealing

Slowly heat to 800~8500 ºC, keep enough time, ensure heat thoroughly. then cooling in furnace to 480 ºC, then cool in air. After annealing, the hardness 92 HBS Max.

- AISI 4130 Steel Hardening & Quenching

4130 Steel is usually used at 18-22 HRc, If needs, AISI 4130 alloy steel can be hardened or Quenching by cold work. Quenching medium: oil

- Tempering Of AISI 4130 Alloy Steel

/ ℃ tempering temperature: 205 ~ 649°C.

After tempering hardness HRC: 18-25 HRc.

Application of Sae AISI 4130 Steel

4130 alloy steel used for Structural products. As below:

Oil and gas sector, like collets, connection rods, conveyor pins, stem assemblies, gears, Bearings

Quality Assured of Sae AISI 4130 Alloy Steel

Quality assured by Our ISO 9001:2008 quality management system. Our all 4130 steel all had by SEP 1921-84 ultrasonic inspection (UT Test). Quality Grade: E/e, D/d, C/c.

If you have any 4130 Alloy steel inquiry and question for Price, Application, hot treatment, please don’t hesitate contact us.

Email: Jack@otaisteel.com

Tel: +86-769- 23190193

Fax: +86-769-88705839