AISI S7 tool steel

OTAI SPECIAL STEEL is S7 tool steel stockholders and suppliers from china. more 16 years experience in AISI S7 tool steel round bar, flat bar and plate supply.

AISI S7 Tool Steel is a high quality impact hot work and cold work tool steel, It belong to the high quality Medium carbon alloy tool steel. Oil Quenched & Tempered Hardenss is 28-34 HRc. AISI S7 steel Annealing delivery hardenss less than 250HB.

Related Specifications ASTM A681 DIN EN 10083/3 JIS G4053 GB GB/T1299

AISI S7 tool Steel Data files Down

Form of Supply

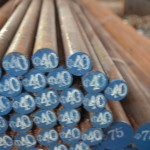

AISI S7 tool steel, we can supply the round bar, steel flat bar, plate, hexagonal steel bar and steel square block. AISI S7 steel Round bar can be sawn to your required lengths. S7 steel Rectangular pieces can be sawn from flat bar or plate to your specific sizes require. S7 Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances as your details require.

- Round

- Plate

- sheet

- Square

Chemical composition

| C(%) | 0.45~0.55 | Si(%) | 0.20~1.00 | Mn(%) | 0.20~0.90 | P(%) | ≤0.030 |

| S(%) | ≤0.040 | Cr(%) | 3.00~3.50 | Mo (%) | 1.30~1.80 | V(%) | ≤0.35 |

Heat treatment Related

- Annealing of AISI S7 Tool steel

Slowly heated the S7 tool steel to 800-810 ℃(1472-1490℉) and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace. The S7 tool steel will get MAX 250 HB (Brinell hardness).

- Hardening of AISI S7 tool steel

S7 steels should be uniformly heated to 650°C (1202°F) until completely heated through. Then rapid increase temperature to 900-950 ℃(1652-1742℉) quenched in oil.

- Tempering of AISI S7 tool steel

Tempering of S7 steels at the required tempering temperature, Soak well at the selected temperature and soak for at least one hour per 25mm of total thickness. Get Rockwell C hardness of 49 to 61.

Temperature [℃] 100 150 200 250 300 400

Hardness [HRc] 61-59 58-56 56-54 55-53 56-55 52-49

Mechanical Properties of AISI S7 tool steel

The mechanical properties of ASIS S7 tool steels are outlined in the following table. All data only for reference.

| Poisson’s ratio | Elastic modulus | Thermal expansion | Yield (0.2%, hardened to 60 HRC) |

Yield (0.2%, hardened to 62 HRC) |

Yield (0.2%,hardened to 50 HRC) |

|

| T (25°C) | T (25°C) | T (20-100°C) | Mpa | Mpa | MPa | |

| 0.27-0.30 | 27557-30458 ksi | 12.4 x 10-6/ºC | 2150 | 2200 | 1350 | |

Applications of AISI S7 tool steel

Typical application for hot work tool steel S7 like core round bar to draw steel pipe. Medium temperature applications include forging, forming and die, punching, punching and reduce death. Other applications include shear blade worn out, and so on.

Regular size and Tolerance

| 1) Hot Rolled round bar | |||

| Diameter (mm) |

Diameter Tolerance (mm) |

Diameter (mm) |

Diameter Tolerance (mm) |

| ≤12.70 | -0.13 ~0.30 | >50.80~63.5 | -0.25~0.76 |

| 12.7~25.40 | -0.13~0.41 | >63.50~76.20 | -0.25~1.02 |

| >25.4~38.10 | -0.15~0.51 | >76.20~101.60 | -0.30~+1.27 |

| >38.1~50.80 | -0.20~0.64 | >101.60~203.20 | -0.38~3.81 |

| 2) Hot Rolled steel plate | |||

| Thickness (mm) |

Thickness Tolerance (mm) |

Thickness (mm) |

Thickness Tolerance (mm) |

| ≤25.4 | -0.41~0.79 | >127~152 | -1.60~2.39 |

| >25.4~76 | -0.79~1.19 | >178~254 | -1.98~3.18 |

| >76~127 | -1.19~1.60 | >254~305 | -2.39~3.96 |

Others S7 tool steel have not specified size, pls contact our experienced sales team.

AISI S7 tool steel round bar and flat sections can be cut to your required sizes. S7 tool steel ground bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. AISI S7 steel is also available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

Contact our experienced sales team to help you with your S7 tool steel questionsadn enquiry by Email or Telphone. The S7 steel questions and inquiry will be reply in 24 hours.