M2 High Speed Steel

M2 tool steel high speed steel China stockholders and suppliers- Otai Special steel. The M2 high speed steel is known for its balanced combination of abrasion resistance, toughness and good red hardness. M2 is a tungsten-molybdenum high speed tool steel, m2 tool steel is used in a variety of applications and worldwide. M2 tool steel is the most popular high speed steel because of its superior qualities. As a result of its low carbon content, M2 tool steel high speed tool steel has an outstanding combination of toughness properties and abrasion resistance when correctly hardened and tempered.

M2 tool steel equivalent with JIS SKH51, SKH9, DIN WN-r 1.3343, GB W6Mo5Cr4V2

M2 high speed steel Related Specifications ASTM A600-1999 M2 HSS steel data pdf down

Related Specifications and Equivalent of ASTM M2 high speed tool steel with others HHS Material Standard

| Country | American | Germany | Japanese | Chinese |

| Standard | ASTM A600-1999 | DIN 17350-1980 | JIS G4403-2000 | GB/T 9943-2008 |

| Grades | M2 | 1.3343 | SKH51 | W6Mo5Cr4V2 |

Chemical Composition contrast of ASTM M2 high speed tool steel with other Equivalent HSS steel Material

| Grade NO. | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Mo(%) | V(%) | W(%) |

| M2 | 0.78~0.88 | 0.20~0.45 | 0.15~0.40 | ≤0.030 | ≤0.030 | 3.75~4.50 | 4.50~5.50 | 1.75~2.20 | 5.50~6.75 |

| 1.3343 | 0.86~0.94 | ≤0.45 | ≤0.40 | ≤0.030 | ≤0.030 | 3.80~4.50 | 4.70~5.20 | 1.70~2.00 | 6.00~6.70 |

| SKH51 | 0.80~0.88 | ≤0.45 | ≤0.40 | ≤0.030 | ≤0.030 | 3.80~4.50 | 4.70~5.20 | 1.70~2.10 | 5.90~6.70 |

| W6M5Cr4V2 | 0.80~0.90 | 0.20~0.45 | 0.15~0.40 | ≤0.030 | ≤0.030 | 3.80~4.40 | 4.50~5.50 | 1.75~2.20 | 5.50~6.75 |

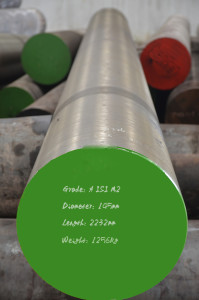

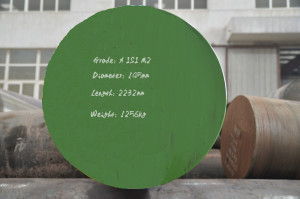

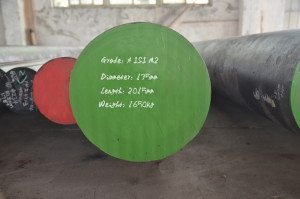

M2 high speed steel Form of Supply

we can supply the round bar, flat, plate and M2 steel square block. M2 round bar can be sawn to your required lengths as one offs or multiple cut pieces. M2 high speed tool steel Rectangular pieces can be sawn from flat bar or plate to your specific sizes. M2 Ground bar can be supplied, providing a quality precision finished bar to tight tolerances.

- Round

- sheet

- Plate

- Square

Regular size and Tolerance of M2 High Speed Steel

| 1) Hot Rolled round bar | |||

| Diameter (mm) |

Diameter Tolerance (mm) |

Diameter (mm) |

Diameter Tolerance (mm) |

| 6.4~15.8 | -0.038 ~0.038 | 181~<206.2 | 0~1.6 |

| 15.8~<77.6 | 0~0.10 | 206.2~<257 | 0~2.4 |

| 77.6~<103 | 0~0.15 | 257~<307.7 | 0~3.2 |

| 103~<181 | 0~0.78 | ≥307.7 | 0~4.7 |

| 2) Hot Rolled steel plate | |||

| Thickness (mm) |

Thickness Tolerance (mm) |

Thickness (mm) |

Thickness Tolerance (mm) |

| ≤25.4 | -0.41~0.79 | >127~152 | -1.60~2.39 |

| >25.4~76 | -0.79~1.19 | >178~254 | -1.98~3.18 |

| >76~127 | -1.19~1.60 | >254~305 | -2.39~3.96 |

Others have not specified size, pls contact our experienced sales team.

Heat treatment related specifications of ASTM M2 high speed steel

- Annealing of HSS M2 high speed tool steel material

ASTM M2 high speed tool steel annealing is recommended before Re-hardening. Heating the M2 high speed tool steel to 850°C , The rate of less than 220°C per hour. Keep at temperature for 1 hour per inch(25.4mm) of thickness (with 2 hours being Min). Cool slowly in the heat treatment furnace . The annealed hardness should be 248 HB(Brinell) or lower.

- Stress Relieving of M2 high speed tool steel material HSS

For get good Machinability, the Stress Relieving is very important. When ASTM M2 high speed tool steel are heavily machined or ground for tools products.it is recommended to stress relieve after machined and prior to hardening to Min the possibility of distortion. For stress relieve heating the component to 680-720°C and soak well about approximately 2 hours, then put in air cool. The tools products can be finish machined before heat treatment.

- Hardening of M2 tool steel HSS material

First Pre-heating M2 steel to 460-500°C, then heating 860-900°C. Third continue heating to 1200-1250°C for hardening temperature and ensure the component is heated through. Care must be taken not to allow the component to remain too long at the hardening temperature. The last Quench in warm oil or brine. If quenching in brine allow the tools to equalize, then complete the quench in air. If quenching in oil remove the component from the oil at about 510°C ,then air cool. The vacuum hardening alos is suitable for M2 high speed steel -M2 HSS material.

- Tempering of M2 high speed tool steel material(HSS steel)

Tempering for M2 steel. Double tempering is mandatory and for tools cut by wire EDM triple tempering is strongly recommended if can. After quenching, the temper the component immediately . Uniformly and thoroughly heating to the selected tempering temperature and hold for at least 2 hours (one hour per inch(25.4mm)of total thickness).

| Temperature (°C) | 300 | 400 | 500 | 550 | 600 | 650 | ||

| Hardness (°C) |

62 | 63 | 64 | 65 | 64 | 61 |

Applications of M2 high speed tool steel hss

M2 High Speed Steel is used high production machine work and is used for various cutting tool, knife and punch and die applications. Some of these applications include Twist drills, taps, milling cutters, reamers, broaches, saws, and knives.

Processing of tool steel M2

M2 High Speed tool steel round bar and flat sections can be cut to your required sizes. M2 High Speed ground steel bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. M2 High Speed steel also is available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

Contact

Contact our experienced sales team to help you with your M2 High Speed Steel questions.by Email or Telphone.

The questions will be reply in 24 hours.