How OTAI Solved 4140 steel gear racks Problems in Mexico

GearWorks S.A. de C.V., a key player in Mexico’s steel gear rack industry, recently faced some serious quality issues that threatened their reputation. Led by Carlos Hernandez, the team at GearWorks was determined to find a reliable supplier to help them overcome these challenges. This is the story of how OTAI stepped in and made a difference.

GearWorks’ Quality Struggles

GearWorks, based in Monterrey, has always prided itself on producing top-notch steel gear racks. These are essential components in many machines, and any quality issues can lead to major problems. Recently, Carlos and his team noticed more and more issues cropping up with their gear racks, affecting their production and customer satisfaction.

The Main Issues

Carlos identified three major problems:

- Inaccurate Dimensions The gear racks were often not matching the exact measurements needed. Even tiny deviations could cause big issues in the machinery they were used in.

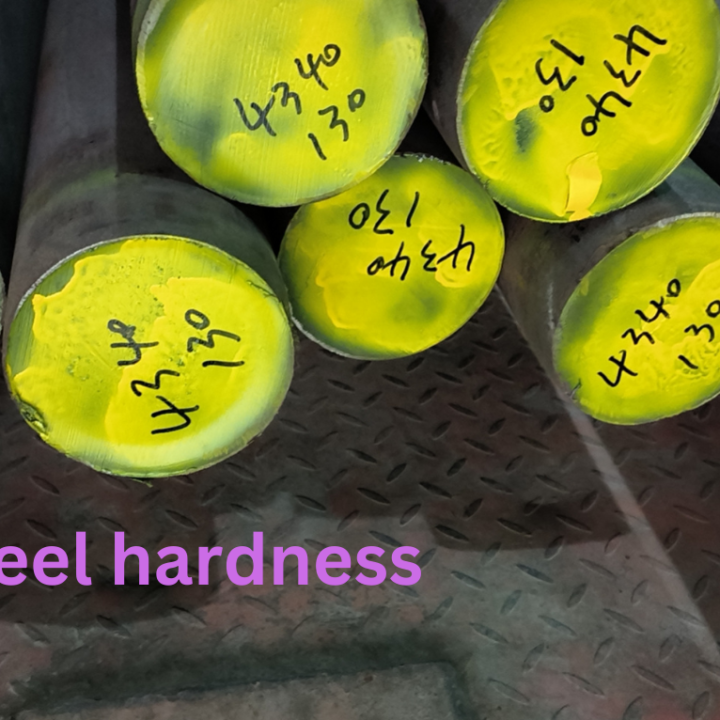

- Weak Material Strength The steel used wasn’t strong enough. Gear racks were wearing out too quickly and breaking down, leading to expensive repairs and downtime.

- Poor Material Quality The steel’s chemical makeup didn’t meet industry standards, resulting in inconsistent performance and reliability.

The Need for a New Supplier

With these problems, Carlos knew they couldn’t stick with their current supplier. The quality issues were damaging their reputation and losing them customers. It was time to find a new, reliable supplier.

Carlos started looking for a supplier who could guarantee top-quality steel and found OTAI, a well-known name in the industry.

How OTAI Came to the Rescue

Carlos reached out to OTAI and was impressed by their rigorous quality control. Here’s how OTAI tackled GearWorks’ problems:

- Accurate Dimensions OTAI understands that precision is crucial. They implemented a strict inspection process, making sure every batch of steel met the exact measurements GearWorks needed. This reduced the dimensional inaccuracies significantly.

- Enhanced Material Strength OTAI uses a specialized heat treatment process to strengthen their steel. This ensures the gear racks can handle high stress and loads, reducing breakdowns and extending their lifespan.

- Superior Material Quality OTAI conducts thorough chemical composition analyses on their steel. Each batch is tested to ensure it meets industry standards and specific customer requirements. This consistency in quality has helped GearWorks produce reliable and high-quality gear racks.

GearWorks’ Turnaround

Thanks to OTAI, GearWorks saw a massive improvement in their production quality. Their gear racks now consistently meet the required specifications, are stronger, and the material quality is top-notch.

Carlos Hernandez said, “Working with OTAI has been a game-changer. The quality of the steel we get now is incredible, and our production has never been smoother. Our customers see the difference, and our reputation for quality is back on track.”

How OTAI Solved 4140 steel gear racks Problems in Mexico

GearWorks’ experience with OTAI highlights how crucial a reliable steel supplier is. OTAI’s dedication to precision, strength, and superior material quality has made them a trusted partner for manufacturers needing top-quality materials.

If you’re facing similar quality issues, consider partnering with OTAI. With our commitment to excellence, we can help you overcome production challenges and achieve great success. Contact OTAI today to learn more about our high-quality 4140 steel and how we can support your manufacturing needs.