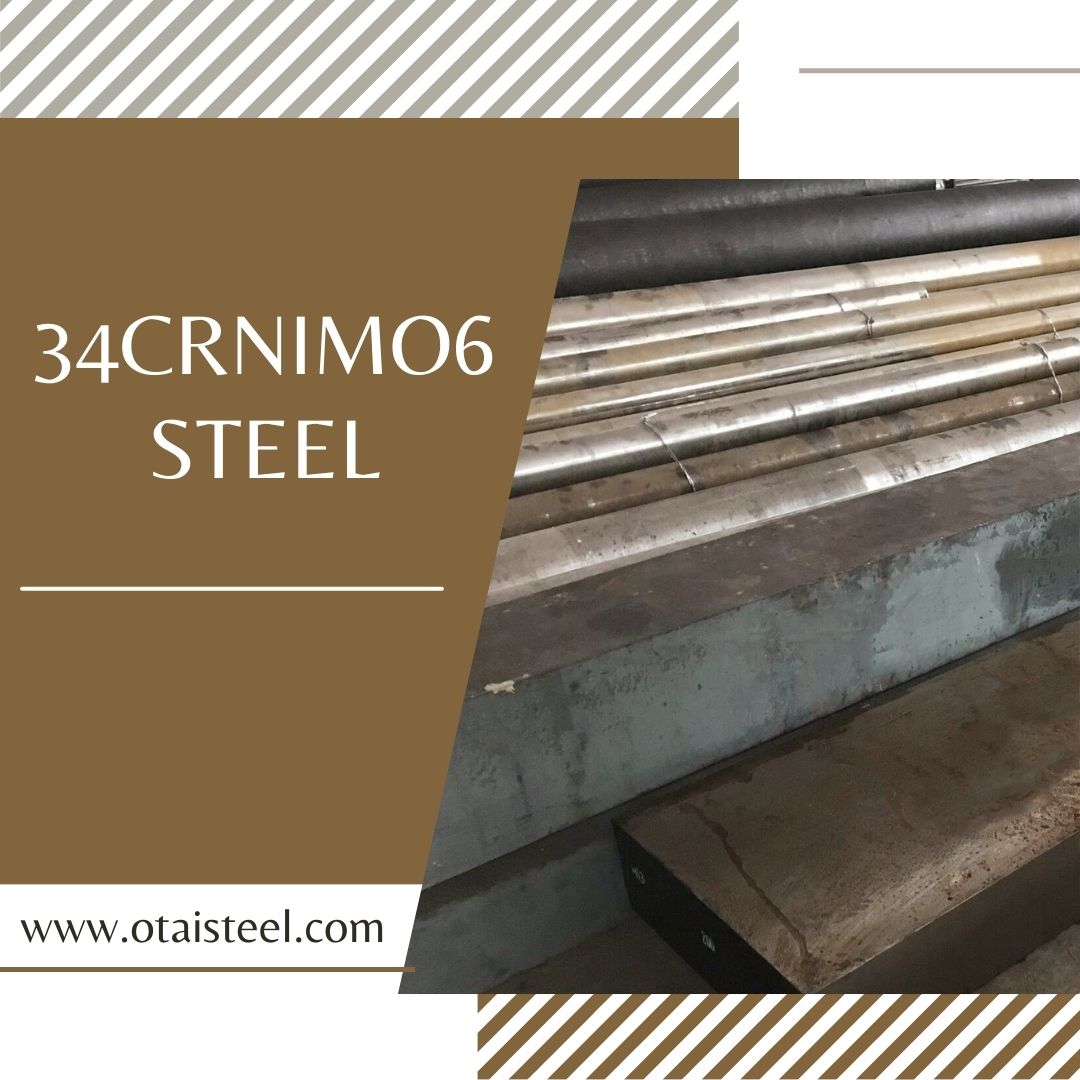

34CrNiMo6 AISI is a low-alloy steel. Its chemical composition consists of 34% carbon (C), 1% chromium (Cr), 1% nickel (Ni), 0.4% molybdenum (Mo), and a balance of iron (Fe). This composition imparts unique characteristics to the steel, making it suitable for a wide range of applications.

34CrNiMo6 AISI is a low-alloy steel. Its chemical composition consists of 34% carbon (C), 1% chromium (Cr), 1% nickel (Ni), 0.4% molybdenum (Mo), and a balance of iron (Fe). This composition imparts unique characteristics to the steel, making it suitable for a wide range of applications.

Composition and Properties

High Strength: One of the standout features of 34CrNiMo6 AISI is its high tensile strength. This makes it an ideal choice for components and structures that require durability and resistance to mechanical stress.

Toughness: The alloy’s toughness is another crucial aspect. It can withstand high impact loads and shock, making it suitable for applications where safety and reliability are paramount.

Hardness: 34CrNiMo6 AISI can be heat-treated to achieve specific hardness levels. This flexibility in hardness adjustment allows for customization based on the intended use.

Applications

Now, let’s explore the diverse applications of 34CrNiMo6 AISI in various industries:

1. Automotive Industry

For manufacturing critical components such as axles, crankshafts, and gears. Its high strength and durability help ensure the safety and longevity of vehicles.

2. Aerospace Industry

In aerospace, 34CrNiMo6 AISI finds use in aircraft landing gear components. The steel’s resistance to fatigue and high-stress environments is vital for safe takeoffs and landings.

3. Oil and Gas Industry

In the oil and gas sector, the steel’s ability to withstand harsh environments and extreme temperatures makes it a preferred choice for drill collars and other downhole equipment.

4. Engineering Machinery

This alloy is employed in the construction of heavy machinery, where it provides the necessary strength and reliability to handle demanding tasks.

5. Power Generation

For the production of turbine shafts and generator components due to its excellent mechanical properties.

Machinability

Another notable feature of 34CrNiMo6 AISI is its good machinability. It can be efficiently machined into various shapes, making it an excellent choice for manufacturing intricate components. This characteristic also simplifies the fabrication process, reducing production costs.

Heat Treatment

Heat treatment plays a crucial role in optimizing the properties of 34CrNiMo6 AISI. Through processes like quenching and tempering, the steel’s hardness and toughness can be adjusted to meet specific requirements. This makes it highly adaptable to different applications across industries.

Environmental Considerations

While 34CrNiMo6 AISI offers a range of benefits, it’s essential to consider its environmental impact. The mining and processing of raw materials to produce steel can have ecological consequences. As such, sustainable practices in production and recycling are gaining importance in the steel industry.

34CrNiMo6 AISI is a versatile and robust steel alloy that finds applications across various industries, from automotive to aerospace and beyond. Its unique composition and exceptional properties make it a preferred choice for components and structures that demand high strength, toughness, and durability. While it excels in many areas, it’s crucial to consider environmental factors and promote sustainable practices in its production and use.