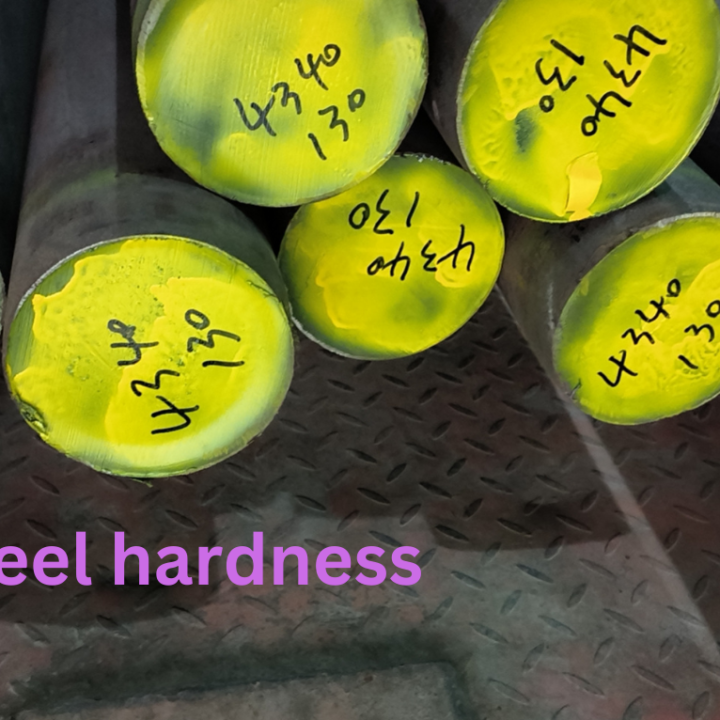

Understanding the Properties and Applications of 4140 Steel

4140 steel is a low alloy steel that contains chromium, molybdenum, and manganese. It has high strength, fatigue resistance, and hardness properties. It is often used in applications such as shafts, gears, bolts, and other automotive components due to its excellent mechanical properties. 4140 steel can be quenched and tempered to improve its toughness and wear resistance. It can also be surface-hardened by carburizing or nitriding to increase its hardness.

Some of the advantages of 4140 steel are:

- High tensile and fatigue strength

- Excellent hardness and toughness

- Good machinability and weldability

- Resistance to wear and tear

- Versatility and adaptability

Some of the disadvantages of 4140 steel are:

- Prone to distortion and cracking during heat treatment

- Requires preheating and post-heating when welding

- Susceptible to corrosion if not protected

- More expensive than some other grades of steel

Some of the products made from 4140 steel are:

- Crankshafts

- Gears

- Axles

- Bolts

- Nuts

- Spindles

- Milling cutters

- Drill bits

- Hydraulic cylinders

- Piston rods

These are just some examples of the many products that use 4140 steel for its strength and durability. (Properties and Applications of 4140 Steel)