8620 VS 4140 – 8620 steel and 4140 steel are both widely used steel in the industry. Let’s compare the differences between 8620 steel and 4140 steel.

What is AISI 8620 & AISI 4140 steel :

8620: AISI 8000 Series Steel; Ferrous Metal; Low Alloy Steel; Low Carbon Steel; Typical uses are: Arbors, Bearings, Bushings, Cam Shafts, Differential Pinions, Guide Pins, King Pins, Pistons Pins, Splined Shafts, Ratchets, Sleeves, etc.

4140: AISI 4140 alloy steel is chromium, molybdenum, manganese containing low alloy steel. It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength.

8620 VS 4140 – Chemical of 4140 & 8620:

| Item | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Mo(%) | Ni(%) |

| 8620 | 0.18-0.23 | 0.15-0.35 | 0.70-0.90 | ≤0.035 | ≤0.04 | 0.40-0.60 | 0.15-0.25 | 0.40-0.70 |

| AISI 4140 | 0.38~0.43 | 0.15~0.35 | 0.75~1.00 | 0.035 | 0.04 | 0.80~1.10 | 0.15~0.25 | / |

8620 VS 4140 – MECHANICAL PROPERTIES

8620 MECHANICAL PROPERTIES:Typical Mechanical Properties – Water Quenched at 830oC and Tempered as Indicated

| Tempering Temperature oC | ||||

| Tensile Strength Mpa | 205 | 425 | 650 | |

| Yield Strength Mpa | 1050 | 930 | 700 | |

| Elongation on 5.65√So % | 765 | 800 | 556 | |

| Izod Impact J | 18 | 20 | 30 | |

| Hardness | 80 | 110 | 140 | |

| HB | 311 | 275 | 207 | |

| Rc | 34 | 29 | 16 | |

4140 MECHANICAL PROPERTIES – The following values are average and may be considered as representative of this grade:

| Properties | Metric | Imperial |

| Tensile strength | 655 MPa | 95000 psi |

| Yield strength | 415 MPa | 60200 psi |

| Bulk modulus (typical for steel) | 140 GPa | 20300 ksi |

| Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 25.70% | 25.70% |

| Hardness, Brinell | 197 | 197 |

| Hardness, Knoop (converted from Brinell hardness) | 219 | 219 |

| Hardness, Rockwell B (converted from Brinell hardness) | 92 | 92 |

| Hardness, Rockwell C (converted from Brinell hardness. Value below normal HRC range, for comparison purposes only) | 13 | 13 |

| Hardness, Vickers (converted from Brinell hardness) | 207 | 207 |

| Machinability (based on AISI 1212 as 100 machinabilities) | 65 | 65 |

8620 VS 4140 – Application :

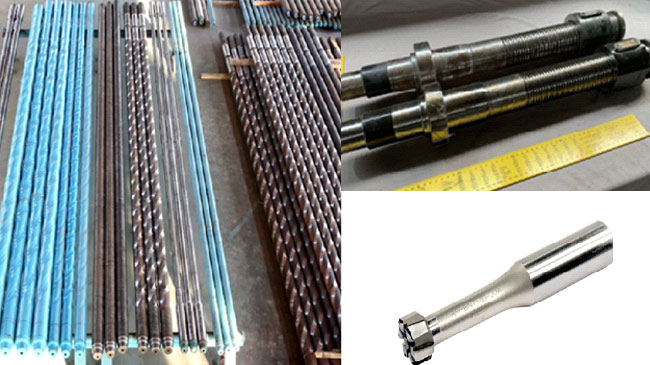

4140 :Applications for 4140 include drill collars, kelly bars, bolts, subs, couplings, reamer bodies, rotary table shafting, valves, zinc-die casting dies, hydraulic machinery shafts, precision lead screws and winch shafts, among others.

8620 :this material is ideal for a wide variety of applications. Gears, pinions, oil pump piston rods and liners, spline shafts, piston pins, cams, jigs, plastic molds, oil tool slips, jaws, gauges,etc

Welcome to contact us to know more about 8620 steel and 4340 steel and get a quote.