In current,There are three main materials for drill rods: 42CrMo4 steel, 40Cr, C45.

42CrMo4 steel is an ultra-high strength steel with high strength and toughness

In current,There are three main materials for drill rods: 42CrMo4 steel, 40Cr, C45.

42CrMo4 steel is an ultra-high strength steel with high strength and toughness, good hardenability, no obvious temper brittleness, high fatigue limit and multiple impact resistance after quenching and tempering, and good low temperature impact toughness. The steel is suitable for manufacturing large and medium-sized plastic molds that require certain strength and toughness.

These characteristics ensure that the hardness of the finished drill rod can reach a high level, at the same time, it has good toughness and good resistance to multiple impacts. The hardness of the drill rod is good, the wear resistance is good, the hardenability is good, and the hardness of the surface of the drill rod and the core can be guaranteed. The absence of tempering brittleness reduces the fracture rate of the drill rod, and the toughness is good. The ability is good, and it is guaranteed that the tail of the drill rod and the piston are not easy to knock off the block. Taken together, it is an ideal material for making drill rods. But the price of raw materials is higher. Therefore, the price of the finished rod is higher. However, the comprehensive cost performance is relatively high.

40Cr is not an ultra-high-strength steel

40Cr is far inferior to 42CrMo4 steel in tempering brittleness, fatigue limit and resistance to multiple impacts, but it has good toughness and hardenability. Therefore, the brazing rod made of it as a raw material is not as good as 42CrMo4 in terms of wear resistance and tail impact. Because it has good toughness, the drill rod is not easy to break. At the same time, the cost of its raw materials is lower than 42CrMo4, so the price of the finished drill rod is more affordable. It is also the most popular type of brazing rod currently on the market. However, in the mine operation, the wear will be faster and the drill rod will be softer. It is not very suitable if you encounter harsh working conditions and environment.

The mechanical properties of C45 steel

Quenching has low hardenability, and it is easy to cause uneven hardness of the drill rod during heat treatment, resulting in deformation or even cracking. The hardness after quenching is about 42 degrees, which is much lower than the 55 degrees of 42CrMo brazing rod. Therefore, the wear resistance is extremely poor. At the same time, the stability of the drill rod is also very poor, and it is easy to break and break the block. But because of its low price, the materials are produced in many places. Therefore, some manufacturers choose when manufacturing low-cost drill rods.

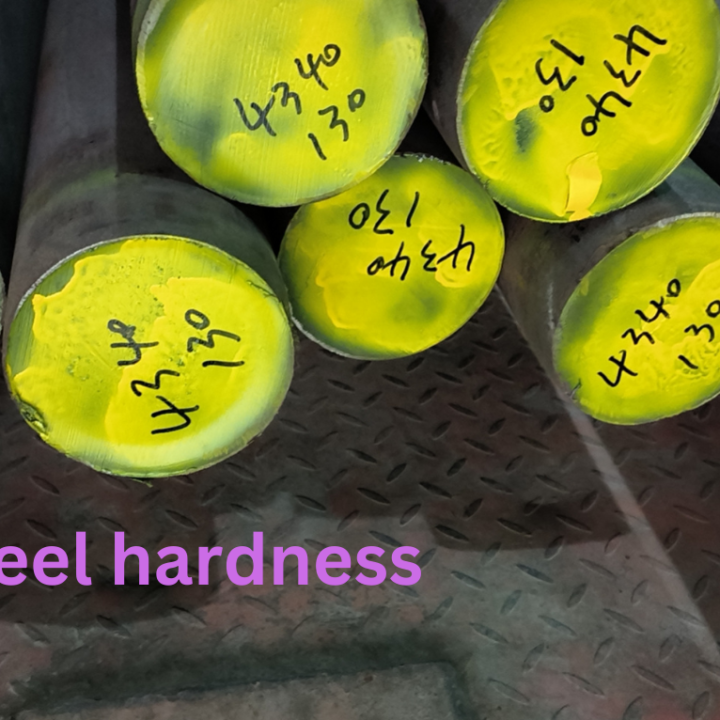

The 42CrMo4 steel wear resistance is good

It is not easy to break and break the block, but the market price is relatively high, and the overall cost performance is the best. It belongs to a good grade in the current market.40Cr as the raw material is affordable and not easy to break, but it is not as good as 42CrMo4 in wear resistance and tail knockout. The real cost performance of mine operations is not higher than 42CrMo4.

Price

The price of the drill rod made of C45 steel is low, but the mechanical performance is far from meeting the requirements of the drill rod. It is not wear-resistant, easy to break, and easy to drop. It is a low-end product in the market.So is there any better material? Of course there are, but because of the high price of raw materials and the difficulty of processing, the finished product of the drill rod is expensive, but it is not as cost-effective as 42CrMo4.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com