42CrMo4 Alloy Steel Material and Its Industrial Applications

Introduction

Modern industry relies heavily on robust materials like 42CrMo4 alloy steel for its foundational strength and reliability. Renowned for its exceptional performance in demanding applications, 42CrMo4 has established itself as a symbol of quality and durability in engineering materials.

Understanding 42CrMo4 Alloy Steel

42CrMo4 is a low-alloy steel enriched with chromium and molybdenum, elements that significantly enhance its mechanical properties. These include high yield strength, excellent toughness, and superior hardenability, making it an ideal choice for applications requiring high wear resistance and load-bearing capacity.

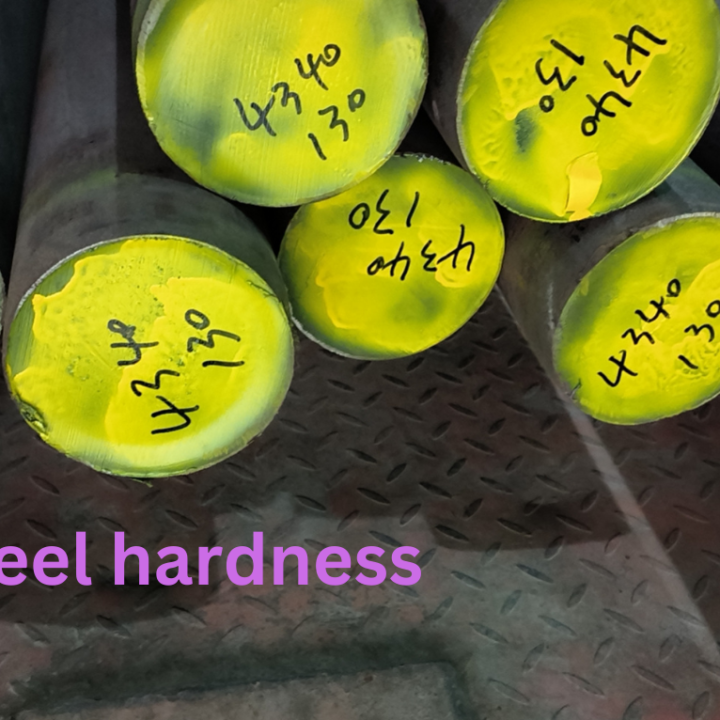

Mechanical Properties and Heat Treatment

The mechanical properties of 42CrMo4 are further optimized through heat treatment processes such as quenching and tempering. These processes allow for precise adjustment of the material’s hardness and ductility, ensuring suitability across a broad spectrum of applications.

Applications in the Mechanical Industry

The mechanical industry drives innovation and demands materials that can meet rigorous standards. 42CrMo4 is extensively used in manufacturing diverse mechanical components due to its superior strength and wear resistance. It is particularly favored for parts subjected to heavy loads and high stress, including gears, bearings, and drive shafts.

42CrMo4 Material Applications: Gear Manufacturing

An exemplary application where 42CrMo4 shines is in gear manufacturing. Its ability to maintain dimensional stability and resist wear ensures gears crafted from 42CrMo4 offer longevity and robust load-bearing capacity. This is critical in industries such as automotive, aerospace, and heavy machinery, where reliability is paramount.

Automotive Industry Applications

In the automotive industry, 42CrMo4 steel is crucial for manufacturing essential parts such as crankshafts, connecting rods, and transmission gears. Its outstanding strength and resistance to fatigue are essential for maintaining optimal performance and durability of these components, especially in the rigorous operating conditions of engines.

Processing and Manufacturing Techniques

The processing of 42CrMo4 involves advanced techniques tailored to maximize its inherent properties. Precision forging and machining techniques are employed to shape the material into intricate components, while rigorous heat treatment guarantees adherence to stringent industry standards.

OTAI’s Unique Selling Propositions

OTAI distinguishes itself in the market through comprehensive service offerings. With an extensive inventory of 42CrMo4 materials ranging from 10mm to 300mm thicknesses, totaling 10,000 tons, OTAI ensures availability to meet diverse client needs. They offer cutting and processing services, reinforced by quality packaging solutions including banding, wooden crates, and rust prevention measures.

Supply Chain and Quality Assurance

OTAI maintains a meticulously managed supply chain to ensure consistent availability of high-quality 42CrMo4 materials. Their rigorous quality assurance processes adhere to international standards, providing clients with assurance of receiving superior products.

Customer Testimonials and Case Studies

Customer testimonials and case studies further underscore the reliability and performance of OTAI’s 42CrMo4 materials. These real-world examples highlight the material’s efficacy in various applications and the exceptional service provided by OTAI.

Conclusion

42CrMo4 alloy steel epitomizes the advancement of material science in enhancing industrial capabilities. Partnering with OTAI ensures access to materials that prioritize performance, reliability, and adherence to the highest standards. Businesses can trust OTAI’s commitment to quality, service excellence, and robust supply chain management for their engineering material needs.