Steel is a remarkable material with a diverse range of alloys, each tailored for specific applications. Two such steel alloys, 4140 vs 52100 steel, are widely used in various industries, each offering distinct properties and advantages. In this comparison, we’ll explore the characteristics of 4140 and 52100 steel, highlighting their differences and common applications. By the end of this article, you’ll have a comprehensive understanding of which steel might be the right choice for your specific needs.

Steel is a remarkable material with a diverse range of alloys, each tailored for specific applications. Two such steel alloys, 4140 vs 52100 steel, are widely used in various industries, each offering distinct properties and advantages. In this comparison, we’ll explore the characteristics of 4140 and 52100 steel, highlighting their differences and common applications. By the end of this article, you’ll have a comprehensive understanding of which steel might be the right choice for your specific needs.

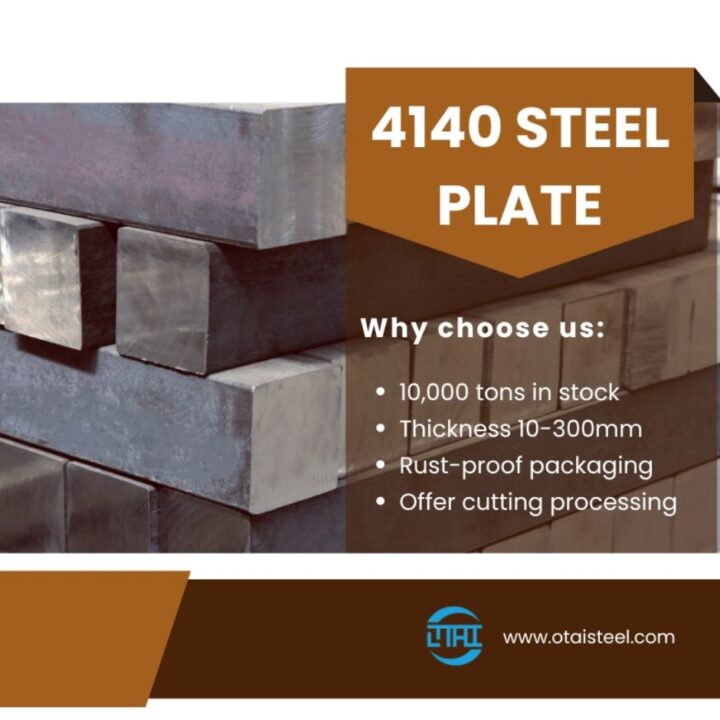

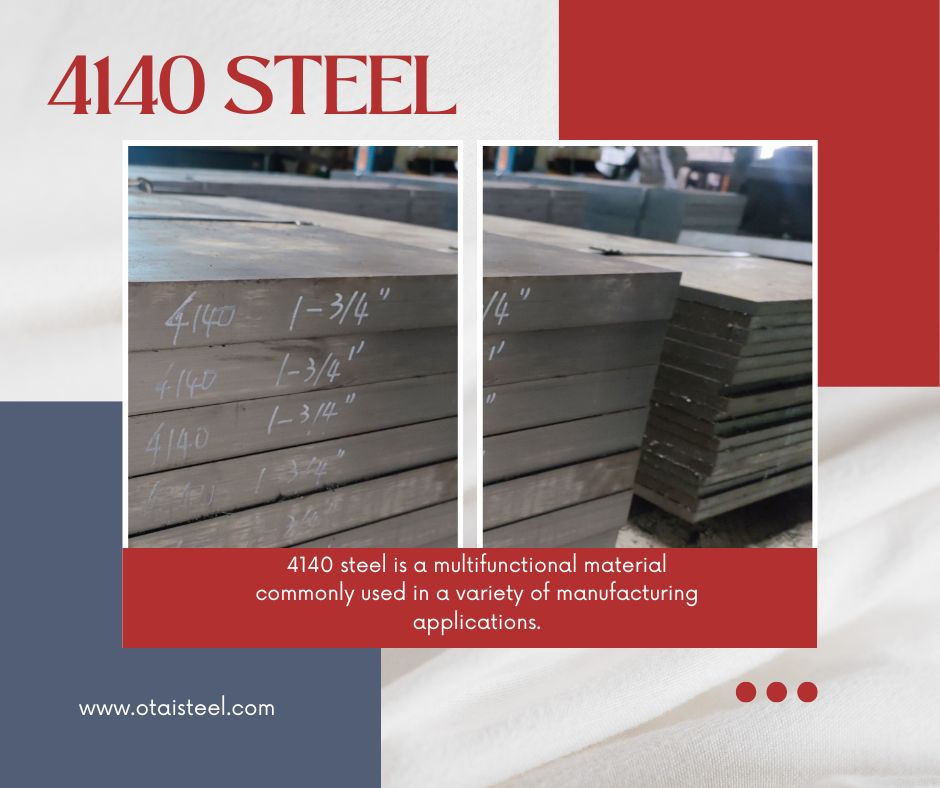

4140 Steel

4140 steel, also known as “chrome-moly” or “chromoly steel,” is a versatile alloy that combines chromium, molybdenum, and carbon to achieve remarkable strength and toughness. This steel alloy is renowned for its excellent impact resistance and moderate wear resistance. The composition of 4140 steel typically consists of approximately 0.40% carbon, 1% chromium, and 0.25% molybdenum, with additional iron and other elements. These components contribute to 4140 steel’s outstanding mechanical properties, making it ideal for various applications.

52100 Steel

52100 steel, on the other hand, is a high-carbon, chromium-bearing steel often referred to as “ball bearing steel.” Its composition includes approximately 1.0% carbon, 1.4% chromium, and small amounts of manganese, silicon, and other trace elements. 52100 steel is highly regarded for its exceptional wear resistance and ability to maintain a sharp edge. This makes it a preferred choice for applications where hardness and abrasion resistance are critical, such as in bearings and cutting tools.

Mechanical Properties

4140 Steel

- Strength: 4140 steel is known for its impressive tensile strength, making it suitable for applications requiring load-bearing components.

- Toughness: Its superior toughness allows 4140 steel to withstand impact and shock, reducing the risk of fractures.

- Hardness: 4140 steel can be heat-treated to achieve various hardness levels, making it adaptable to different requirements.

52100 Steel

- Hardness: 52100 steel is characterized by its exceptional hardness, making it an ideal choice for applications where resistance to wear and abrasion is crucial.

- Durability: This steel excels in maintaining its edge and shape, which is valuable in precision equipment like bearings.

- Fatigue Resistance: 52100 steel’s fatigue resistance is a key attribute for components subject to repeated stress.

Applications

4140 Steel

- Automotive: 4140 steel is widely used in the automotive industry for components such as axles, crankshafts, and gears due to its high strength.

- Aerospace: It finds application in aerospace engineering, particularly in critical components like landing gear and aircraft engine parts.

- Manufacturing: 4140 steel is essential in the production of various tooling and machinery.

52100 Steel

- Bearings: 52100 steel’s hardness and wear resistance make it a top choice for manufacturing high-precision bearings.

- Cutlery and Blades: Many knife makers prefer 52100 steel for its edge retention and sharpness.

- Anti-Friction Applications: It is utilized in applications where minimal friction and high durability are required.

Conclusion

In the world of steel alloys, 4140 vs 52100 steel stand out for their unique characteristics and applications. While 4140 steel offers exceptional strength and toughness, making it ideal for load-bearing components, 52100 steel shines with its remarkable hardness and wear resistance, making it a top choice for bearings and cutting tools. Your choice between these two alloys should be guided by the specific requirements of your project or application.