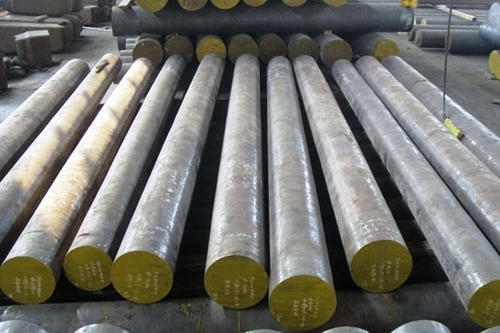

36CrNiMo16 alloy steel

Description

36CrNiMo16 alloy steel is used for mechanical parts and all kinds of engineering components and contains one or several kinds of alloy element in steel,36CrNiMo16 Alloy structural steel is widely used in ships, vehicles, aircraft, missiles, weapons, railways, Bridges, pressure vessels and so on.

36CrNiMo16 alloy steel Chemical composition

| C | Si | Mn | Ni | P | S | Cr | Mo |

| 0.32 – 0.39 | max 0.4 | 0.5 – 0.8 | 3.6 – 4.1 | max 0.025 | max 0.025 | 1.6 – 2 | 0.25 – 0.45 |

All Grades Comparison:

| EN | Material No. | BS | NF |

| 36CrNiMo16 | 1.6773 | 835M30/EN30B | 35NCD16 |

Mechanical Properties

| Dia/Thickness(mm) | Tensile Strength Rm (Mpa) | Yield Strength R2 (Mpa) | Elongation (longitudinal direction) Al (%) | Elongation (transverse direction) At (%) | Impact properties (KV J) (longitudinal) | Impact properties (KV J) (transverse) |

| 160 max | 1000 min | 800 min | 11 min | 8 min | 45 min | 22 min |

| 160-330 | 1000 min | 800 min | 11 min | 8 min | 45 min | 22 min |

| 330-660 | 1000 min | 800 min | 11 min | 8 min | 45 min | 22 min |

Heat Treatment:

Forging

Heat the steel carefully to the forging temperature of 1000-1100°C, soak well. After forging, cool slowly in a furnace to 100°C maximum and anneal immediately.

Annealing

To obtain the softest condition heat carefully to 630-650°C. Soak for a minimum of 2 hours, then cool in the furnace or in air. It is advisable to repeat this treatment to obtain the best machining characteristics.

Stress Relieving

Where the machining operations have been severe, we recommend stress relieving EN30B alloy steel before finish machining and hardening. Heat carefully to 630-650°C then cool in the furnace or in still air.

Hardening

Heat uniformly to 810-830°C and when thoroughly soaked at this temperature cool in the air or quench in oil according to mass. Hardening from neutral salt baths will help to prevent scaling or decarburization and is strongly recommended. Preheat at 300-400°C, raise to the hardening temperature of 810-830°C, quench into salt standing at 300-320°C. Withdraw and cool in air. Alternatively, tools may be vacuum hardened. If desired, hardened and tempered tools can be cyanide hardened to give a shallow carburized case to die surfaces with increased hardness values up to Rockwell C56-60. Temper as soon as tools are hand-warm.

Tempering

Reheat to the relevant tempering temperature. Soak for at least 2 hours per 25mm of ruling section. Withdraw from the furnace and cool in still air. Tempering between 275-450°C is not advised as tempering within this range will reduce the impact value.

Application

36CrNiMo16 alloy steel are widely used in construction and project structure,also used in making rebar,house frame,pylon,bridge,cars,container,cramp, cramp bar,crane hook,crane mast,crane rail,crane rope,crane runway,crank,crank bearing,drill press spindle,Tractor turn axis,cam,camshaft,gear,etc.

Contact

If you have any 36CrNiMo16 alloy steel inquiries and questions for Price, Application, hot treatment, Please don’t hesitate to contact us.

Email: Jack@otaisteel.com

Tel: +86-769- 23190193

Fax: +86-769-88705839