20CrMo alloy structural steel

OTAI SPECIAL STEEL is 20CrMo alloy structural steel stockholders and suppliers from China. more than 25 years of experience in 20CrMo steel round bar, flat bar and plate supply.

20CrMo is an alloy structural steel with high hardenability, no temper brittleness, poor weldability, similar to 45# weldability, a certain tendency to cold crack, good machinability, and cold strain plasticity.

20CrMo steel is a kind of Chinese alloy steel for engineering and mechanical structure purposes, which is generally used in quenching or tempering or carburizing and quenching. 20CrMo material has high heat strength, good hardenability, no temper brittleness, cold strain plasticity, good machinability, and weldability.

Generally used in quenched and tempered or carburized and quenched state, it can be used to replace 20CrMnTi, 20Cr, 20MV, 20Mn2, 20CrNi, and other materials. It is used to manufacture high-pressure pipes and various fasteners that work in non-corrosive media and media containing nitrogen and hydrogen mixtures with a working temperature of less than 250°C, as well as higher-grade carburized parts, such as gears, shafts, etc.

20CrMo steel properties as below:

Form of Supply

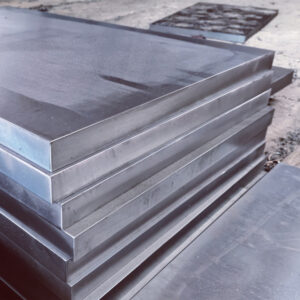

20CrMo steel, we can supply the round bar, steel flat bar, plate, hexagonal steel bar, and steel square block. Round bars can be sawn to your required lengths as one-offs or multiple-cut pieces. Rectangular pieces can be sawn from flat bars or plates to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

- Round

- sheet

- Square

- Plate

Chemical composition

| C(%) | 0.17~0.24 | Si(%) | 0.17~0.37 | Mn(%) | 0.40~0.70 | P(%) | ≤0.030 |

| S(%) | ≤0.030 | Cr(%) | 0.80~1.10 | Mo (%) | 0.15~0.25 | Cu(%) | ≤0.030 |

20CrMo steel vs 25CrMo4 steel

20CrMo and 25CrMo4 are both types of alloy steel.

20CrMo is a low-carbon steel used for engineering and mechanical purposes.

25CrMo4 is a heat-resistant steel used for structural purposes.

20CrMo Alloy Steel Mechanical Properties

- Yield strength: ≥ 685 MPa

- Tensile strength: ≥ 885 MPa

- Elongation: ≥12%

- Rate of reduction in area: ≥50%

- Impact absorbing energy: ≥ 78 J

- Material Brinell hardness: ≤ 197 (Annealed or high temperature tempered steel rod)

- Sample size: 15mm

Heat Treatment Specification

- First quenching heating temperature: 880 °C (Quenching agent: water, oil)

- Tempering heating temperature: 500 °C (agent – water, oil)

Equivalent Grades

20CrMo material equivalent to US ASTM, European Germany DIN EN, British BS EN, France NF EN, Japanese JIS, and ISO standard. (For reference)

| 20CrMo steel equivalent | |||||||||||||

| China | USA | Germany | Japan | France | UK | ||||||||

| Standard | Grade | Standard | Grade | Standard | Grade (Steel Number) | Standard | Grade | Standard | Grade (Steel Number) | Standard | Grade (Steel Number) | ||

| GB/T 3077 | 20CrMo | AISI SAE; ASTM A29/A29M |

4120 | DIN EN 10083-3 | 25CrMo4 (1.7218) | JIS G4053 | SCM420 | NF EN 10083-3, NF A35-551 |

25CrMo4 (1.7218), 18CD4 |

BS EN 10083-3, BS 970 Part 1 |

25CrMo4 (1.7218), 708M20 |

||

Quality Assured Supply

20CrMo steel is supplied in accordance with our ISO 9001 : 2023 registration.

Contact our experienced sales team to help you with your 20CrMo steel questions and inquiries by Email or telephone. The questions will be replied to in 24 hours.

Email: jack@otaisteel.com

Tel: +86 769 2319 0193

Fax: +86-769-88705839