1.2343 hot work tool steel

OTAI SPECIAL STEEL is 1.2343 hot work tool steel stockholders and suppliers from China. more 16 years experience in steel round bar, flat bar and plate supply.

DIN 1.2343 steel is a hot work tool steel, the US equivalent material is H11 steel, which has excellent machinability and polishability, good high toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance.

The application of steel 1.2343 ESU (X37CrMoV5-1) is die casting molds for light metal processing, cylinders and pistons on cold chamber machines, metal extrusion tools, etc.

1.2343 hot work tool steel properties as below:

Form of Supply

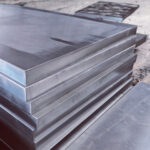

1.2343 hot work tool steel, we can supply the round bar, steel flat bar, plate, hexagonal steel bar and steel square block. Round bar can be sawn to your required lengths as one offs or multiple cut pieces. Rectangular pieces can be sawn from flat bar or plate to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

- Round

- sheet

- Square

- Plate

Chemical composition

| C(%) | 0.33 – 0.41 | Si(%) | 0.8 – 1.2 | Mn(%) | 0.25 – 0.50 | P(%) | ≤0.030 |

| S(%) | ≤0.020 | Cr(%) | 4.8 – 5.5 | Mo (%) | 1.1 – 1.5 | V(%) | 0.3 – 0.5 |

Mechanical Properties

- Annealed/softened condition – hardness: <229 HB

- Hardness in tempered condition: min >48 HRC

- Hardness after hardening: 57.3 – 57.5 HRC

- Hardness after tempering in the following temperatures:

- 300 C = 54,4 – 54,5 HRC

- 350 C= 54,9 HRC

- 400 C = 55,4 – 55,6 HRC

- 450 C = 55,9 – 56,2 HRC

- 500 C= 56,3 HRC

- 550 C= 53,2 HRC

- 600 C = 47,5 – 47,7 HRC

- Linear expansion coefficient: 12,7 * 10-6 K-1

- Thermal conductivity: 38 W * m-1 K-1

Heat treatment Related

-

- Softening annealing at a temperature of 800 – 840 C

- Hardening at a temperature of 980 – 1050 C

- Tempering at a temperature of 450 – 550 C

- Relaxing annealing in the range of 470 – 550 C

- Nitriding at a temperature of 470 – 550 C

Application

Alloy tool steel for hot working for moulds for die casting of aluminium alloys, magnet, zinc, pressing pipes, copper alloy bars and light metals under pressure.

It is characterized by very high hardenability, resistance to tempering, possibility of working at high temperatures and low susceptibility to forming a surface crack net.

Disadvantages of the grade are low sensitivity to rapid temperature fluctuations during operation, low impact and shock resistance. Before use the tools must be warmed to a minimum temperature of 200 C, but must not exceed the tempering temperature.

It is used for the production of hot working knives, die inserts for presses and forging machines, screws, dies, moulds for plastics, stamps, mandrels, punches, copper rolling mills.

The steel is also available after ESR electroslag melting, which guarantees high purity – recommended for moulds for casting non-ferrous metal alloys under pressure, and ESF which guarantees fine-grainability.

Contact our experienced sales team to help you with your 1.2343 tool steel questions and enquiry by Email or Telphone. The questions will be reply in 24 hours.

Email: jack@otaisteel.com

Tel:+86 769 2319 0193

Fax: +86-769-88705839