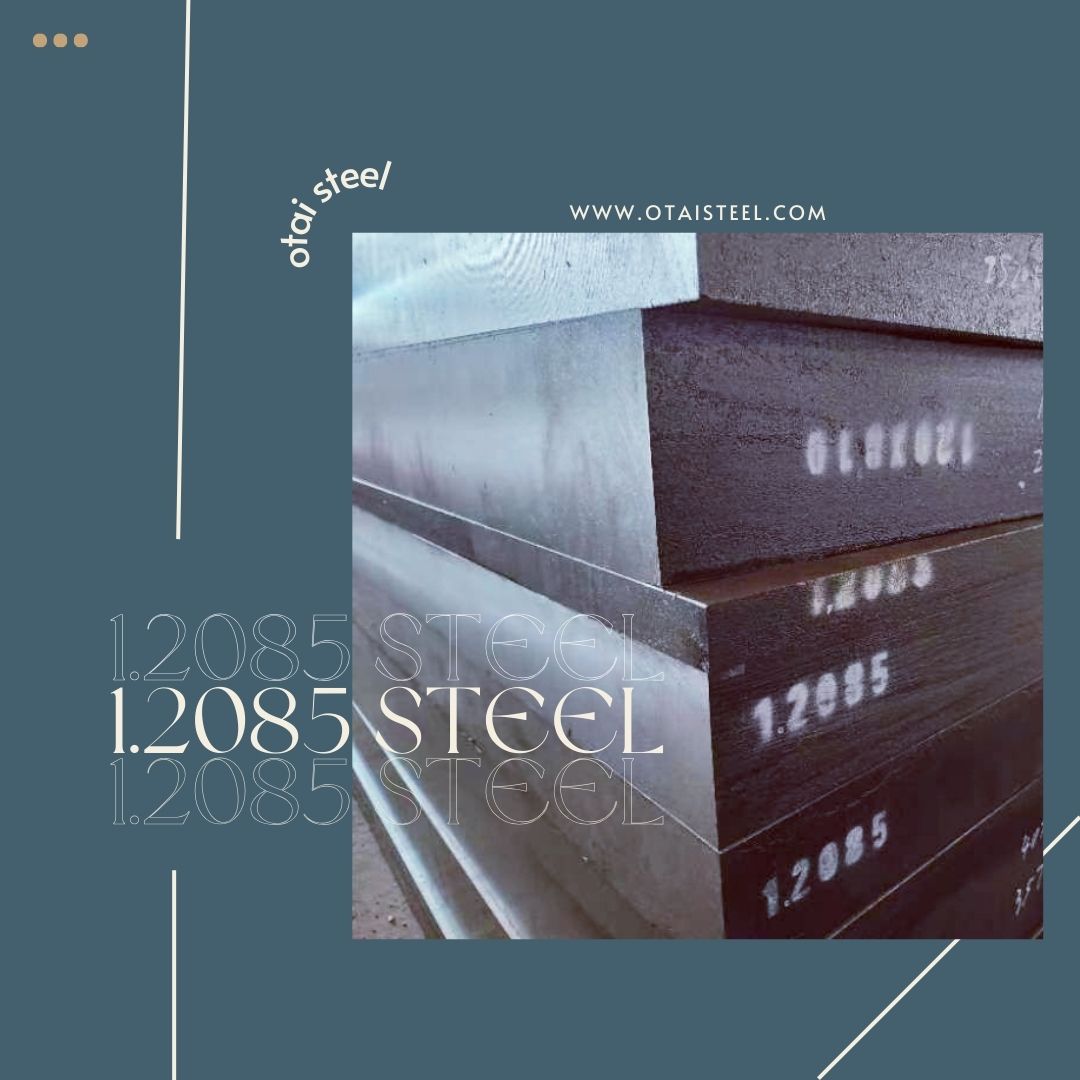

1.2085 steel, known by various names including 420HC and X46Cr13, possesses unique mechanical properties that make it a sought-after material for a wide range of applications. In this article, we’ll dive into the mechanical properties of 1.2085 steel, exploring its hardness, toughness, and more.

1.2085 steel, known by various names including 420HC and X46Cr13, possesses unique mechanical properties that make it a sought-after material for a wide range of applications. In this article, we’ll dive into the mechanical properties of 1.2085 steel, exploring its hardness, toughness, and more.

Hardness of 1.2085 Steel

1.2085 steel is celebrated for its impressive hardness, a property that’s essential for many industrial and practical applications. The hardness of 1.2085 steel is typically measured using the Rockwell Hardness Scale and can reach values in the range of 55-58 HRC (Rockwell C).

Toughness and Impact Resistance

While 1.2085 steel is known for its hardness, it also exhibits good toughness and impact resistance. This is crucial in applications where the material may experience sudden shocks or loads. The combination of hardness and toughness makes 1.2085 steel an ideal choice for blades and cutting tools that need to maintain their sharpness while withstanding impacts.

Wear Resistance

1.2085 steel’s excellent wear resistance is another standout feature. This property is a result of its high carbon content, which allows it to maintain a sharp edge over extended periods of use. This makes 1.2085 steel a preferred material for knives, industrial cutting tools, and other wear-prone applications.

Corrosion Resistance

The chromium content in 1.2085 steel plays a significant role in its corrosion resistance. The formation of a protective chromium oxide layer on the surface of the steel makes it highly resistant to corrosion, staining, and rust. This feature is particularly valuable in applications exposed to moisture and chemicals, such as surgical instruments and marine components.

Machinability

1.2085 steel also offers good machinability. It can be shaped and processed with relative ease, making it a practical choice for manufacturers and engineers. The presence of small amounts of manganese and silicon enhances the steel’s machinability, allowing for efficient manufacturing processes.

Heat Treatment

The mechanical properties of 1.2085 steel can be further optimized through heat treatment. Heat treatment processes like hardening and tempering can fine-tune the steel’s hardness and toughness, ensuring it meets specific application requirements. Hardening, in particular, is crucial for achieving the desired hardness, which is often followed by tempering to improve toughness.

Applications of 1.2085 Steel

The exceptional mechanical properties of 1.2085 steel make it suitable for a wide array of applications, including:

- Cutting Tools: Its hardness and wear resistance make 1.2085 steel an ideal choice for cutting tools like drills, end mills, and blades for industrial applications.

- Knives: 1.2085 steel is a preferred material for knife blades. Whether in the culinary field for kitchen knives or in outdoor activities for hunting and survival knives.

- Surgical Instruments: The combination of corrosion resistance, hardness, and toughness is well-suited for surgical instruments such as scalpels and forceps.

- Mold Making: In the manufacturing industry, 1.2085 steel is used for creating molds for plastics and other materials, ensuring dimensional stability and wear resistance.

- Food Processing Equipment: Its corrosion-resistant properties make 1.2085 steel an excellent choice for components used in food processing and packaging machinery.