Otai Special Steel is Inconel 625 Alloy Steel China supplier and Stock. We supply in Steel round bar, plate, flat bar, square bar, hexagonal bar, pipe /tube / hollow bar. Inconel625 are molybdenum, niobium main strengthening solid solution strengthening type nickel-base superalloy deformation elements, has excellent resistance to corrosion and oxidation resistance to engage, from cryogenic to 980 ℃ have good tensile and fatigue properties, and salt stress corrosion under foggy atmosphere. Therefore, it can be widely used in the manufacture of aircraft engine parts, aerospace structural components and chemical equipment. Good processing and welding properties of the alloy, can supply all kinds of plate, bar, pipe, wire, strip and forgings.

Inconel 625 (NO6625) physical and chemical properties of high-temperature alloys

1, the thermal properties:

(1), Inconel 625 melting temperature range: 1290 ~ 1350 ℃ [1].

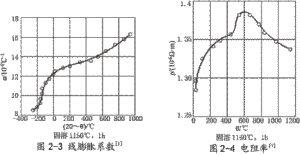

(2) thermal conductivity: Figure 2-1.

(3), specific heat capacity: Figure 2-2.

(4), linear expansion coefficient: Figure 2-3.

2, Inconel 625 Density: ρ = 8.44g / cm3.

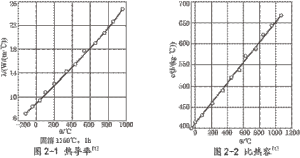

3, Inconel 625 electrical properties: the resistivity of the alloy shown in Figure 2-4.

Inconel 625 magnetic

non-magnetic alloy

Inconel 625 (NO6625) high temperature alloy structure

1, Inconel625 phase transition temperature

2, Inconel625 time – temperature – transformation curve organizations

3, Inconel625 alloy structure: alloy solid solution state of austenite matrix and a small amount of TiN, NbC, and M6C phase, after 650 ~ 900 ℃ long-term aging, precipitated phase γ “, δ, M23C6 . and M6C after 650 ~ 700 ℃ long-term aging is mainly precipitated γ “, the alloy at room temperature, high temperature strength significantly increased plasticity declined, but remained at a high level; after 780 ~ 850 ℃ aging main precipitation δ phase, although the intensity It has increased, but fell more plastic alloy. Only after 900 ℃ aging small amount of precipitates, and therefore the mechanical properties of a solid solution state similar. δ phase orthogonal structure sheet Ni3Nb, and needle Wilcoxon organizations exist

Inconel 625 (NO6625) superalloy and process performance requirements

1, Inconel625 formability:

Alloy hot and cold forming good performance. Forging steel ingot heating temperature is 1120 ℃, open forging temperature not lower than 1030 ℃, stop forging temperature not lower than 930 ℃; when forging, the final amount of deformation of not less than 15% to 20%. Rolling heating temperature is 1120 ~ 1160 ℃, beginning rolling temperature not lower than 1050 deg.] C, stop rolling temperature not lower than 930 ℃, semi-finished cold-rolled sheet a deformation of 25% to 30%, the amount of deformation of the finished product is not less than 30%. Intermediate and finished quenching temperature of 1100 ℃ ± 10 ℃ [1,8].

2, Inconel625 welding performance:

Alloy Welding good performance, under protective atmosphere for arc welding with additional material be present or tungsten alloy, can also be soldered and resistance seam welding.

3, Inconel625 parts heat treatment process:

Stress Relief: 900 ℃; annealing: 930 ~ 1040 ℃, 1h; solution heat treatment: 1090 ~ 1200 ℃, air cooling or water cooling. When the alloy at no higher than 650 ℃ work, according to the requirements of hot rolled, cold rolled or annealed material. When operating at temperatures above 650 ℃, the requirements for having good tensile strength and fatigue properties of the components may be annealing process, the requirements of good creep and rupture properties of the parts can be solution treated.

4, Inconel625 surface treatment: the alloy surface oxide is removed first caustic, and then in nitric acid – hydrofluoric acid – acid aqueous solution.

5, Inconel625 cutting and grinding performance:

It should be used cemented carbide or high speed steel cutting tools. Cutting tools used should have a positive rake angle. Recommended cutting speed when processing water-based coolant, recommended more viscous coolant at low speed machining.

Inconel 625 (NO6625) superalloy different specifications and supply status and form

1, species classification: Otai special steel alloys can produce a variety of special Inconel625 seamless, Inconel625 steel, Inconel 625 bar, Inconel 625 forgings, flanges Inconel 625, Inconel 625 ring, Inconel 625 pipe, Inconel625 steel, wire and Inconel625 matching welding consumables.

2, the delivery status: seamless: acid solution + white, length can be cut to length; plate: solid solution, pickling, trimming; pipe: white + RT% acid solution testing, forgings: annealing and light vehicles; bar with wrought state, surface finish or a light vehicle; cold-rolled strip, soft-state solution, descaling delivery; wire pickling solution to disc or straight strips, finely ground solution straight light delivery.