A2 tool steel | SKD12 | 1.2363 | X100CrMoV5-1 cold work steel

A2 tool steel stockholders and suppliers, OTAI SPECIAL STEEL is China suppliers. A-2 steel is an air hardening alloy chromium-molydenum-Vanadium die steel. As a cold work steel grade containing 5% chromium. In applications require greater size stability, A2 steel is preferable than O1 tool steel.

Cold work A2 tool steel grade in standard ASTM A681-1999

ASTM A681-1999 include the A2 cold work tool steel, and others cold work tool steel, hot work tool steel, high speed steel. It is standard specification of hot work tool steels, hot work tool steel, high speed steel for alloy steel tool, mould, die application, such as hot rolling or hot forging steels or cold drawn steel grade.

AISI A2 tool steel Applications

A2 steel is a cold work tool steel. Typical application such as Blanking die, molding die, blanking die, stamping die, stamping die, die, extrusion die, boxing, shear knife blade, instrumentation, knurling tools, volume, head and machine parts.

AISI A2 tool steel Supply Range

A2 steel round bar, flat bar, square, A2 steel plate Size range as below:

- JIS SKT4 Steel Round Bar: 8mm-800mm

- JIS SKT4 Steel Cold Drawn Bar: 5mm-70mm

- JIS SKT4 Steel Plate: 10-1500mm x 200-1300mm X Length

- Cold work A2 tool steel equivalents steel grade

A2 is an high alloy Chrome Molybdenum hot work tool steel grade number. AISI A2 steel standards and steel grades equivalent as below:

- BS 4659, BA2

- GB 1299,Cr5Mo1V

- JIS, SKD12

- DIN X100CrMoV5-1

- W-Nr 1.2363

- AISI A2 tool steel Properties

Steel material A2 Chemical Composition

| Grade Number | Standard | C | Si | Mn | P | S | Cr | V | Mo |

| A2 | ASTM A681-1999 | 0.95~1.05 | 0.10~0.50 | 0.40-1.00 | 0.030 Max | 0.30 Max | 4.75~5.50 | 0.15~0.50 | 0.90~1.40 |

ASTM A2 Steel Mechanical Properties

Machinability (based on carbon tool steel): 65%;

Bulk modulus (typical for steels): 140 GPa ;

Poisson’s ratio : 0.27-0.30;

Modulus of elasticity (@20°C/68°F): 190-210 GPa

Heat Treatment ASTM A2 Steel

A2 steel material heat treatment including the heating rate, soaking times, cool, these such as the different shape and size of each A2 steel component.

Forging: 2000-2100°F, Temperature, cool slowly;

Annealing: 1545-1580°F,Temperature, cool slowly, rate: 25°F per hour to 1110°F ,then cool in air.

Stress relieving: 1020-1200°F,Cool slowly in furnace to 950°F, then cool in air.

Hardening: 1700-1800°F,in air cool.

Pre-heating: 1450-1500°F

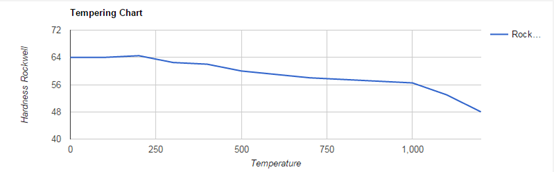

Tempering:

. Contact Otai speical steel for buy A2 tool steel Materials inquiry

Email: jack@otaisteel.com TEL: 0086-769-33232622 FAX: 0086-769-88705839